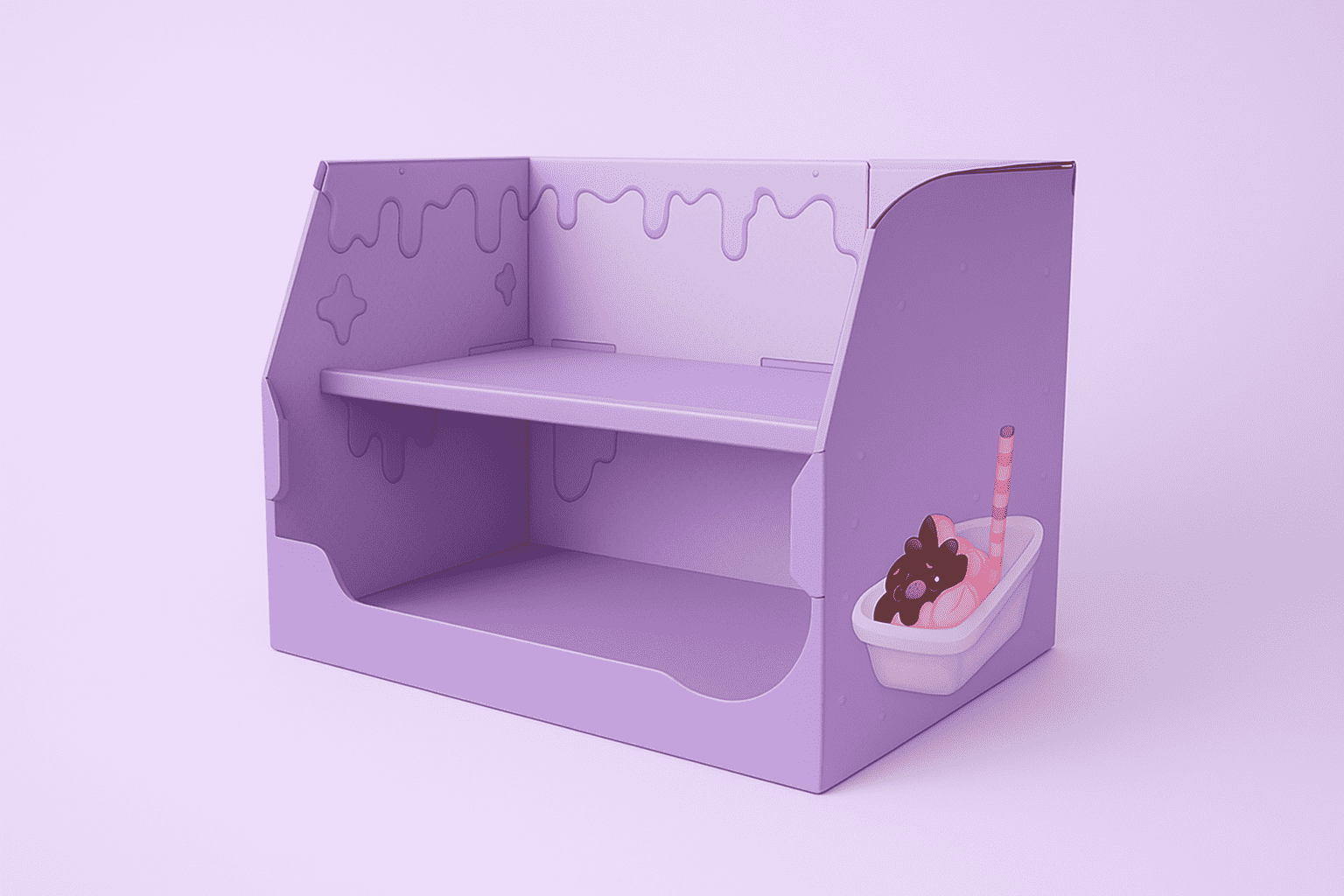

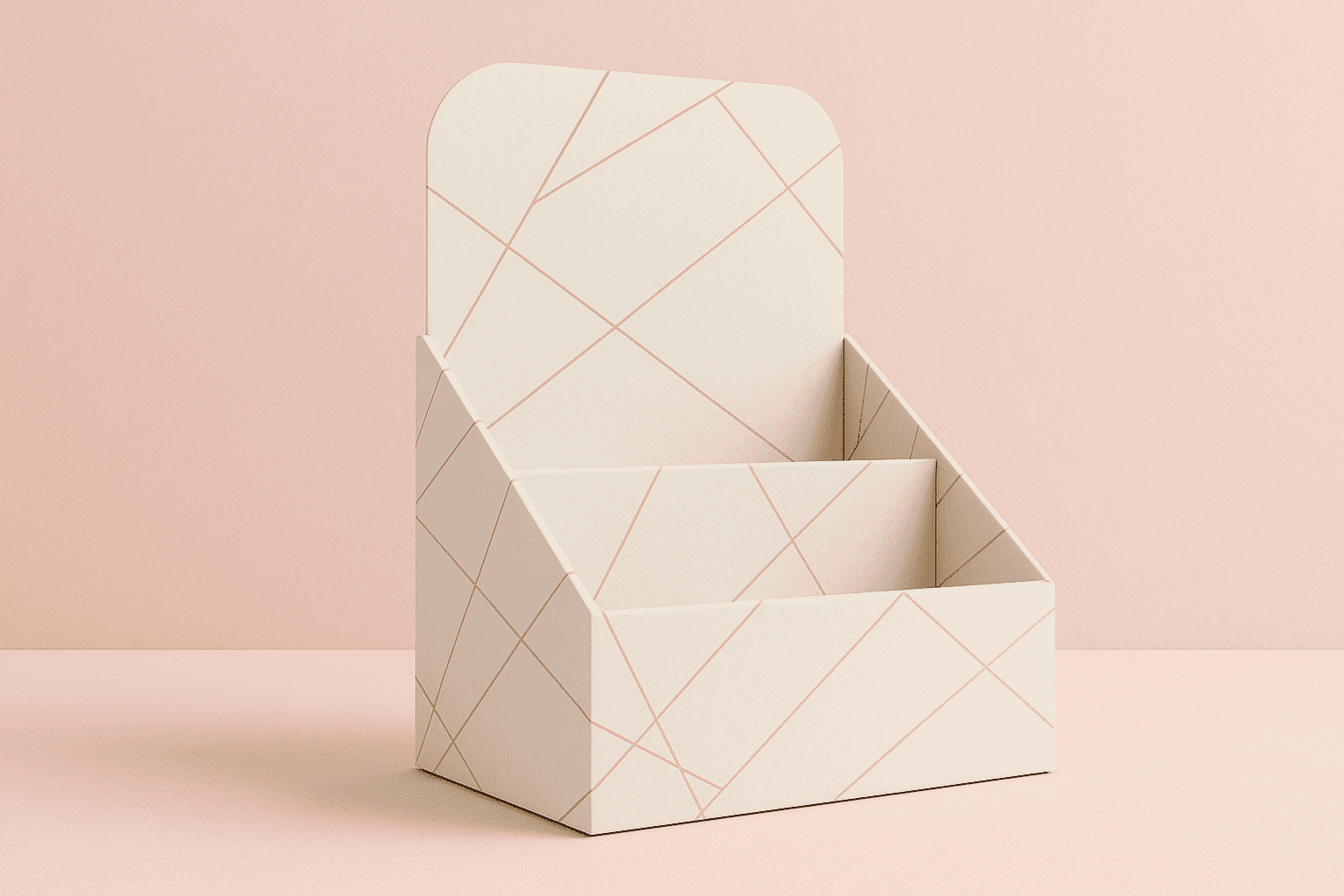

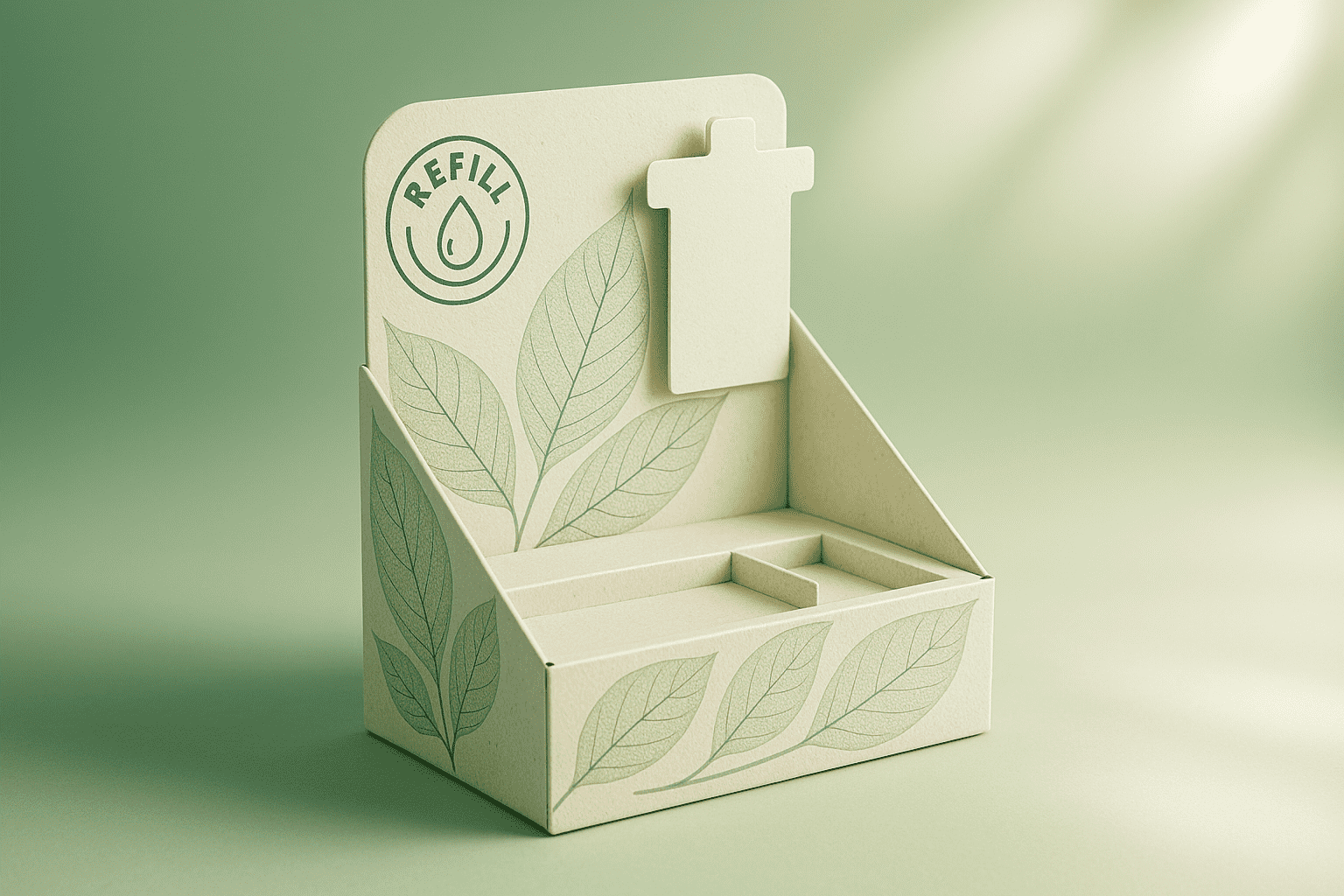

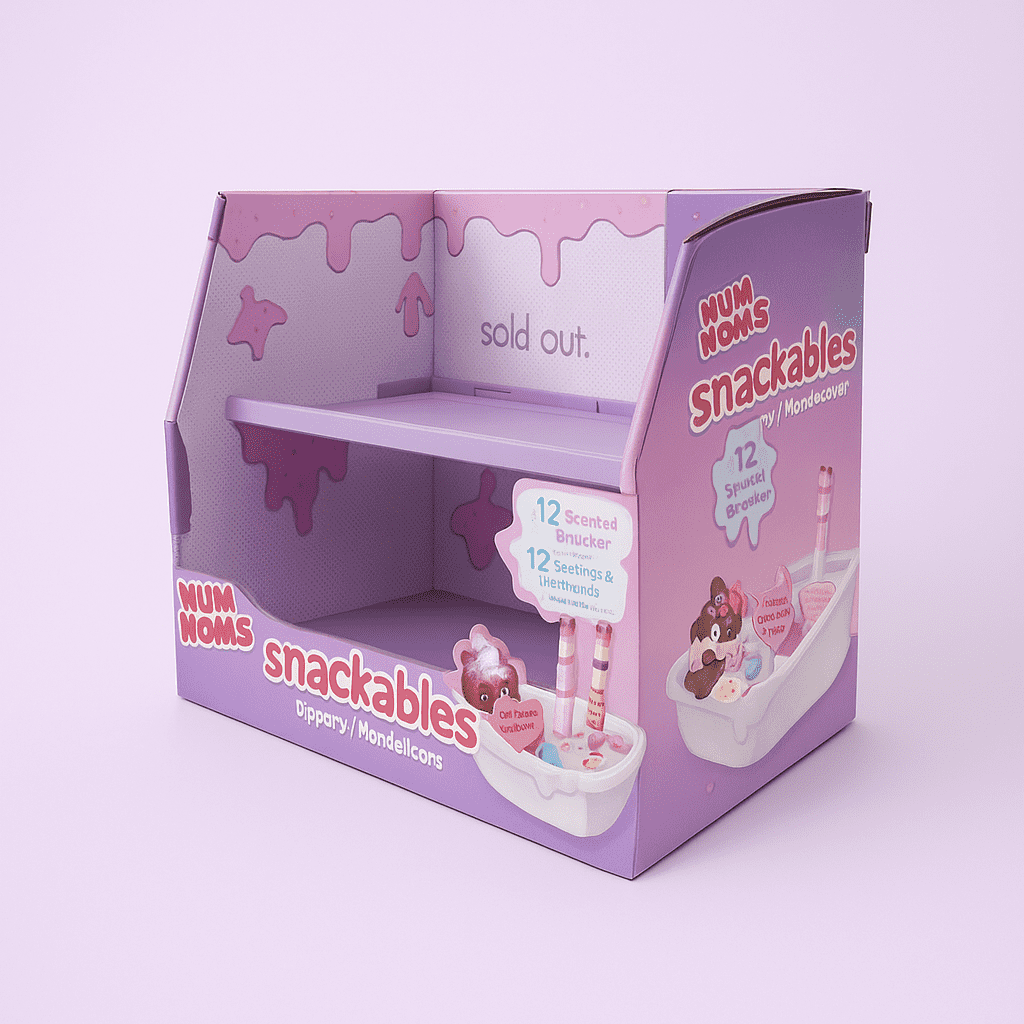

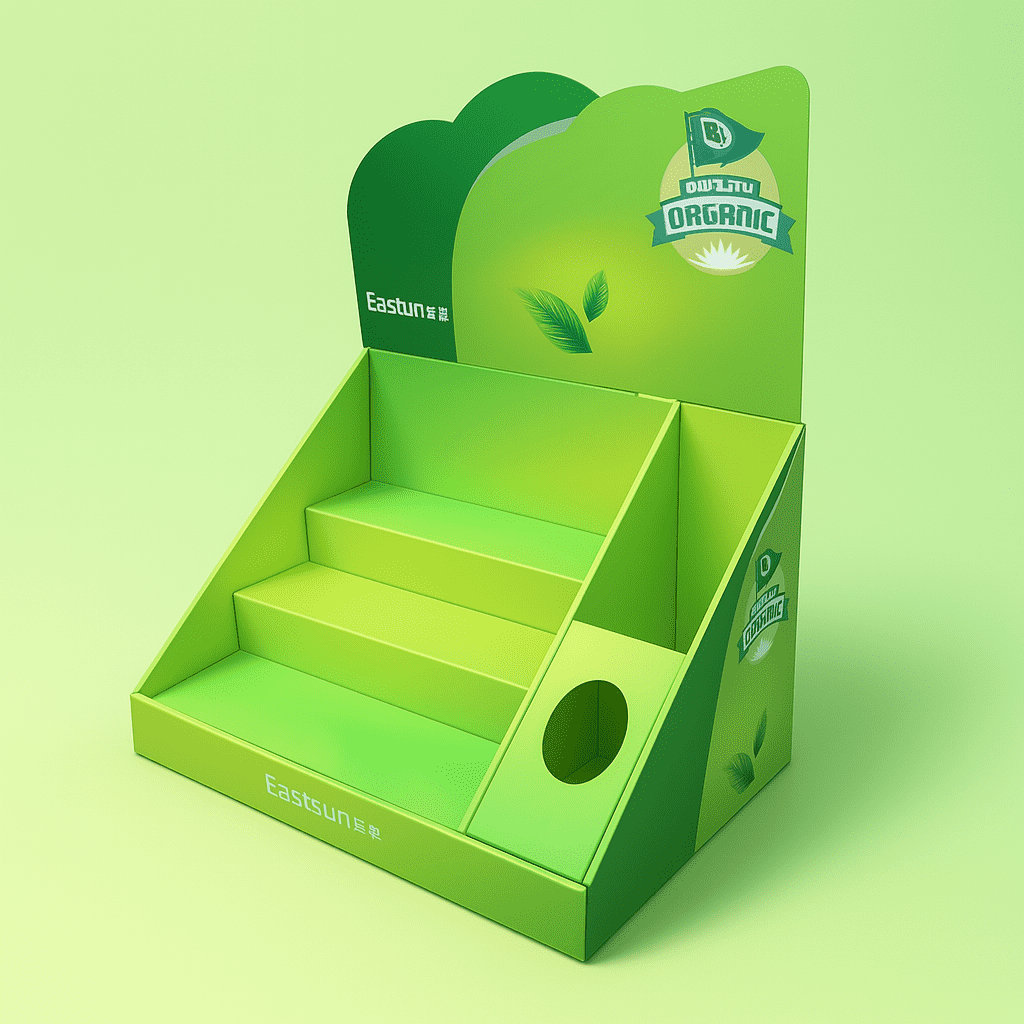

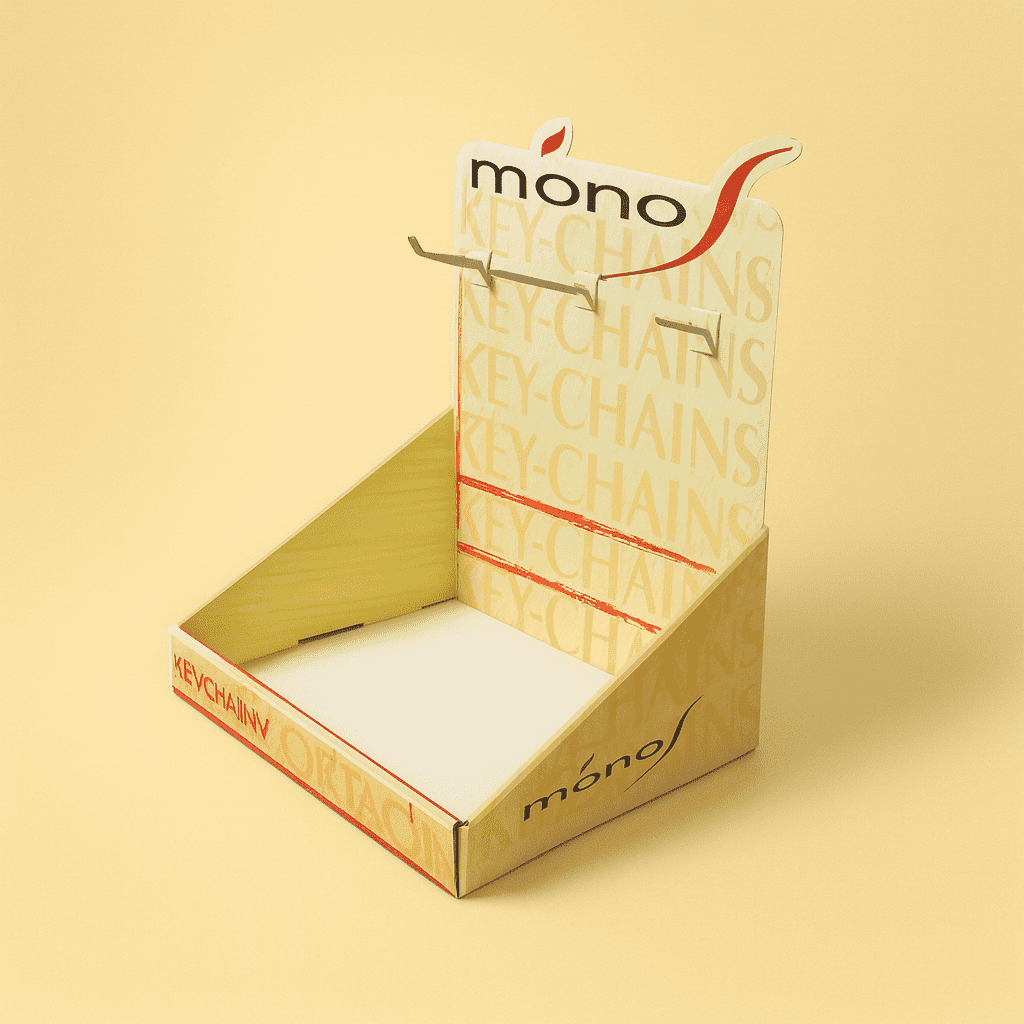

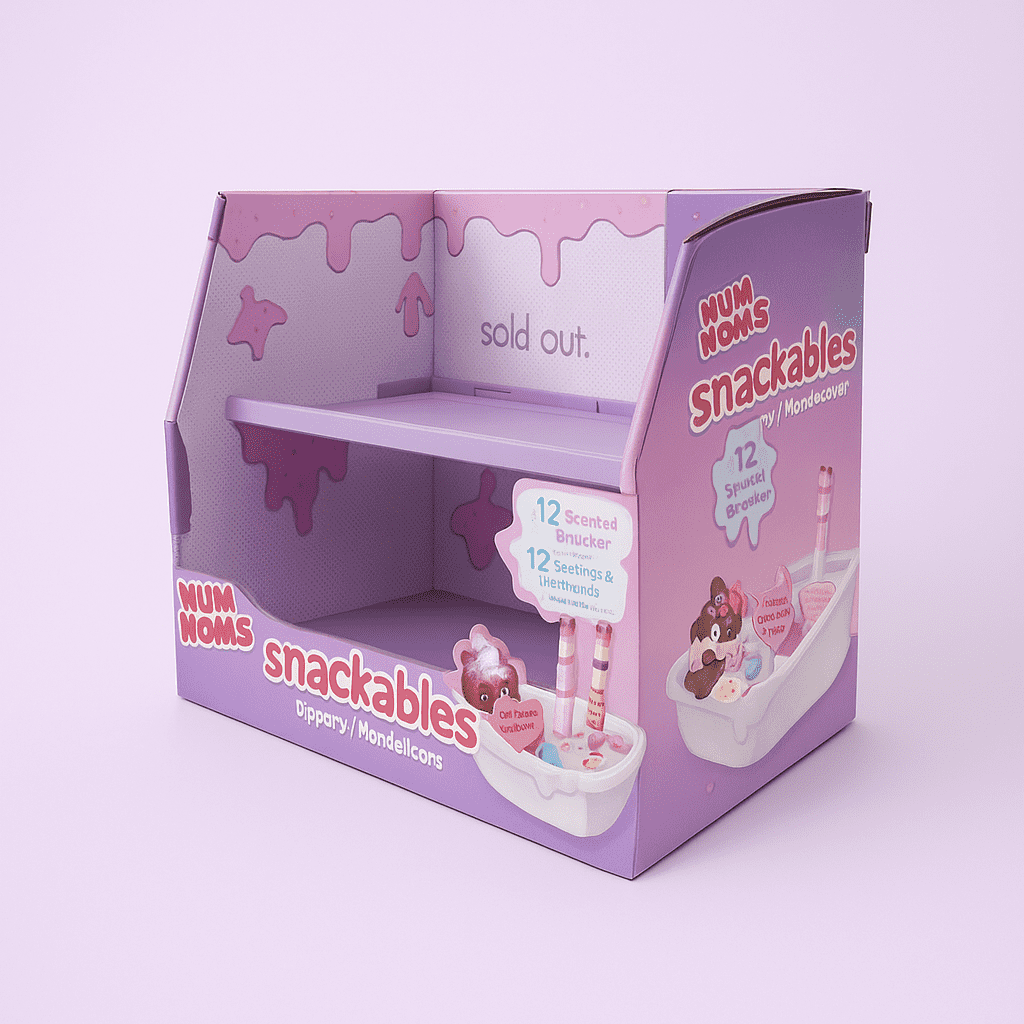

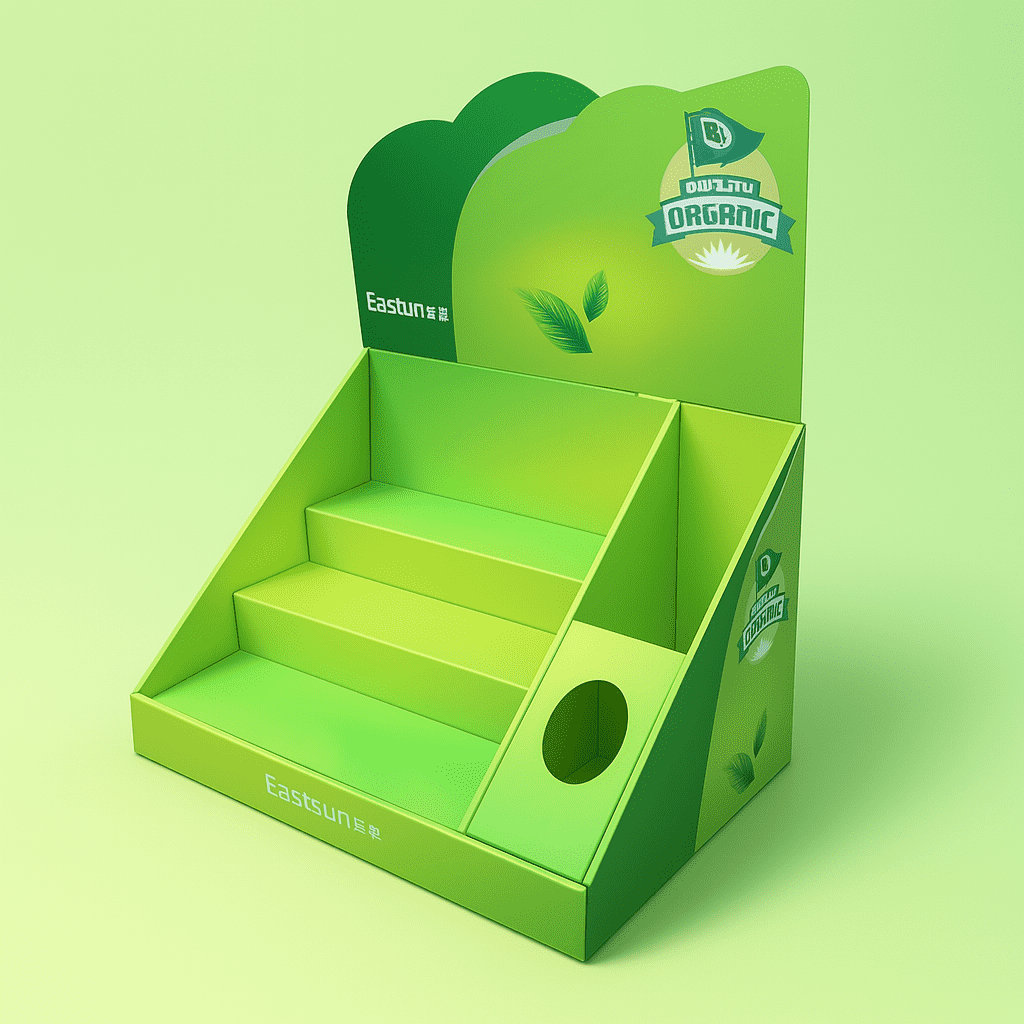

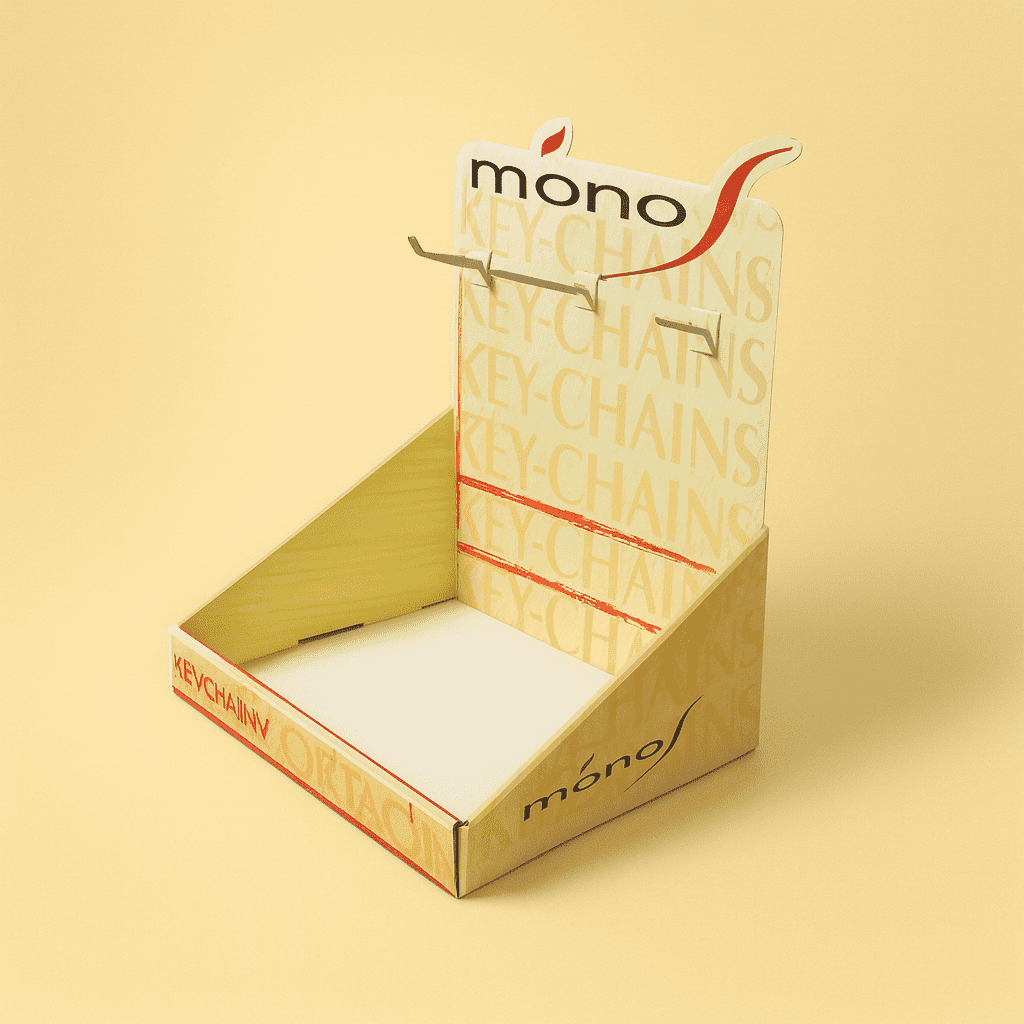

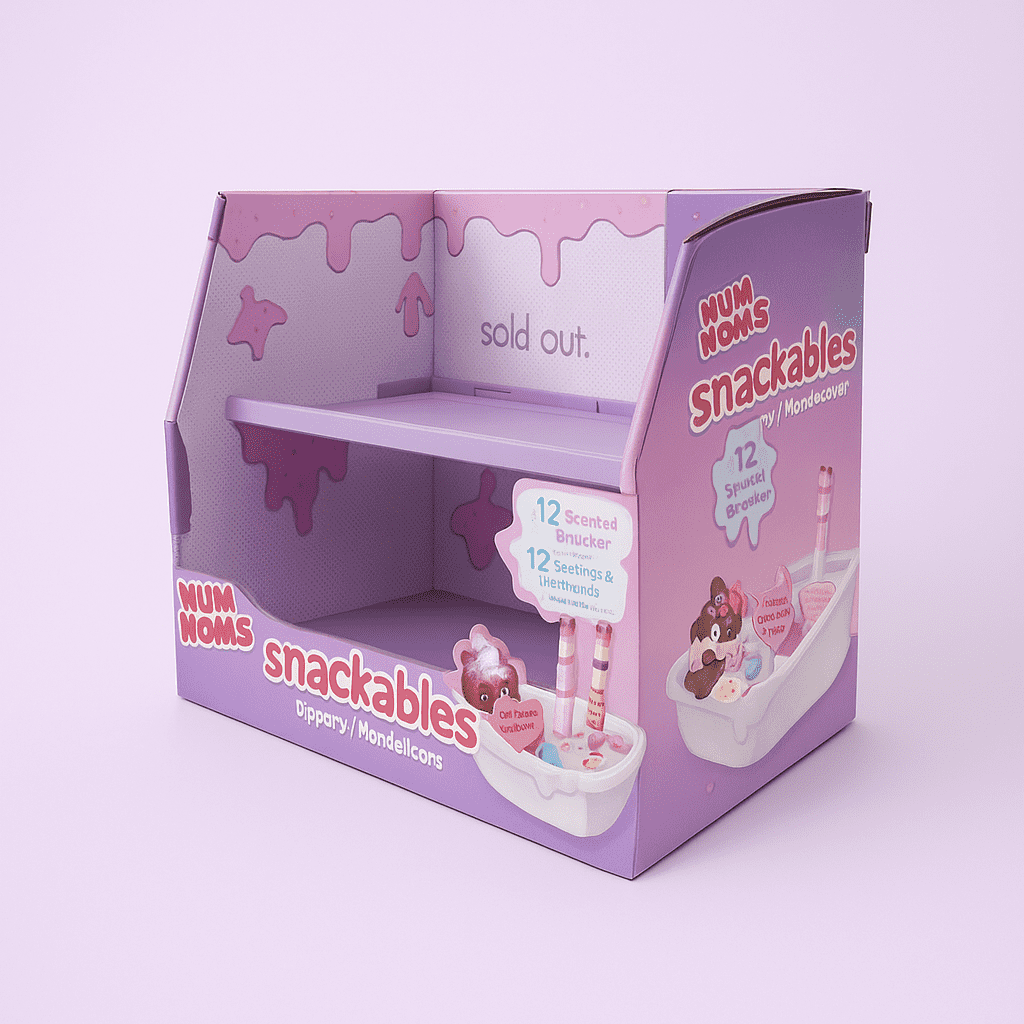

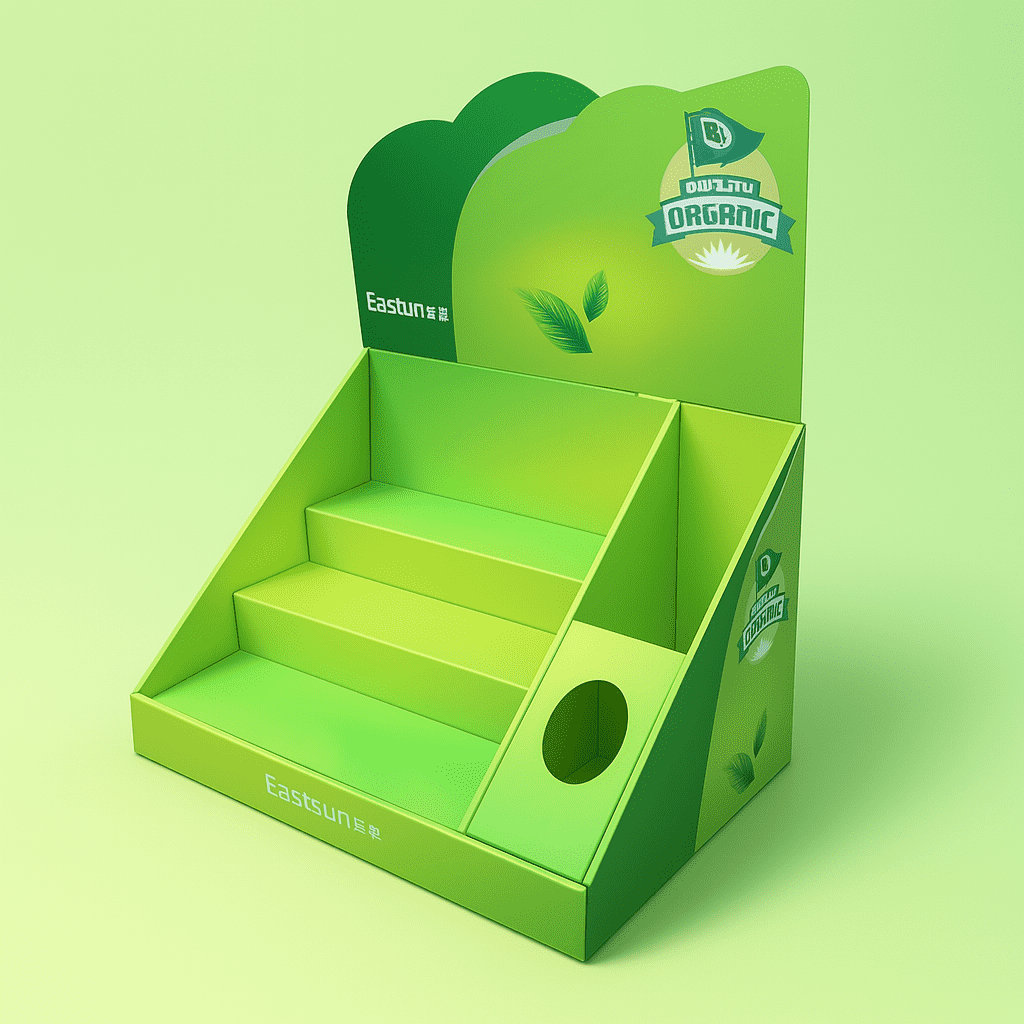

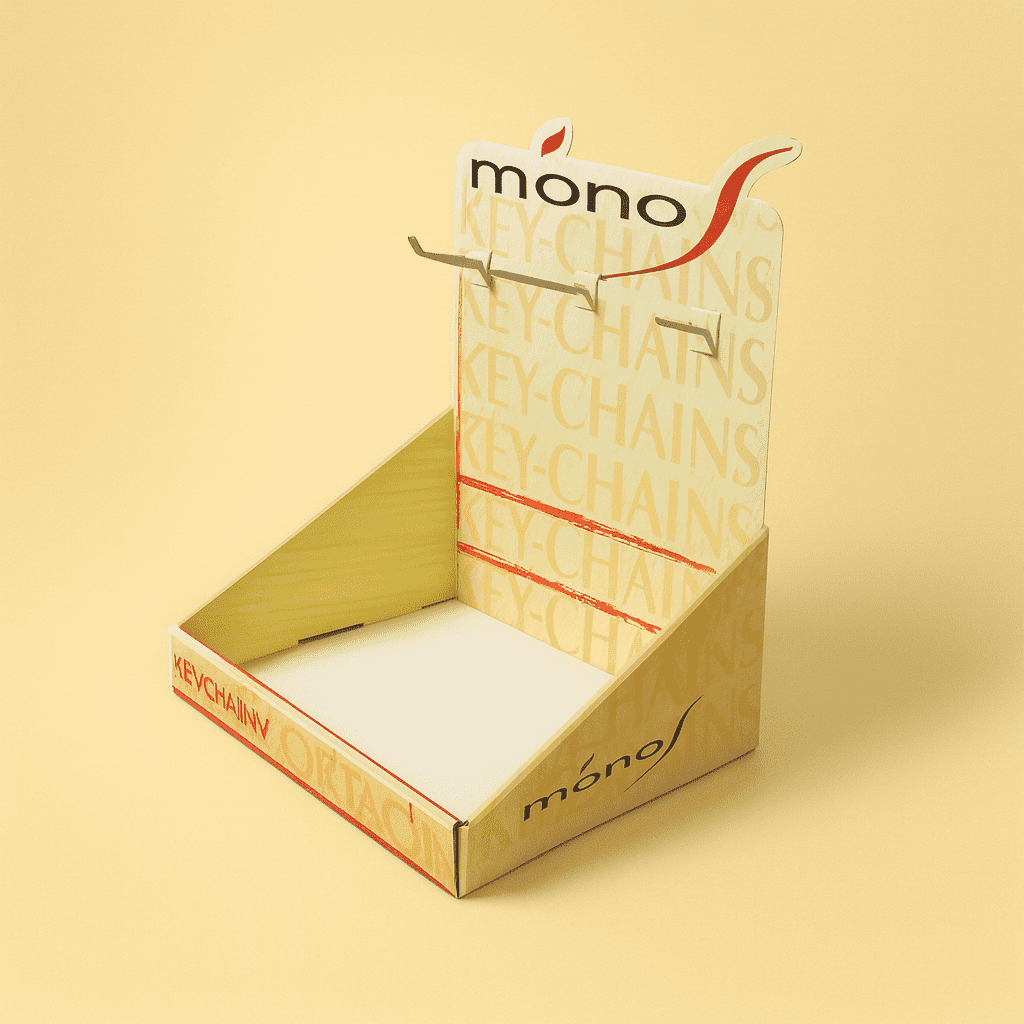

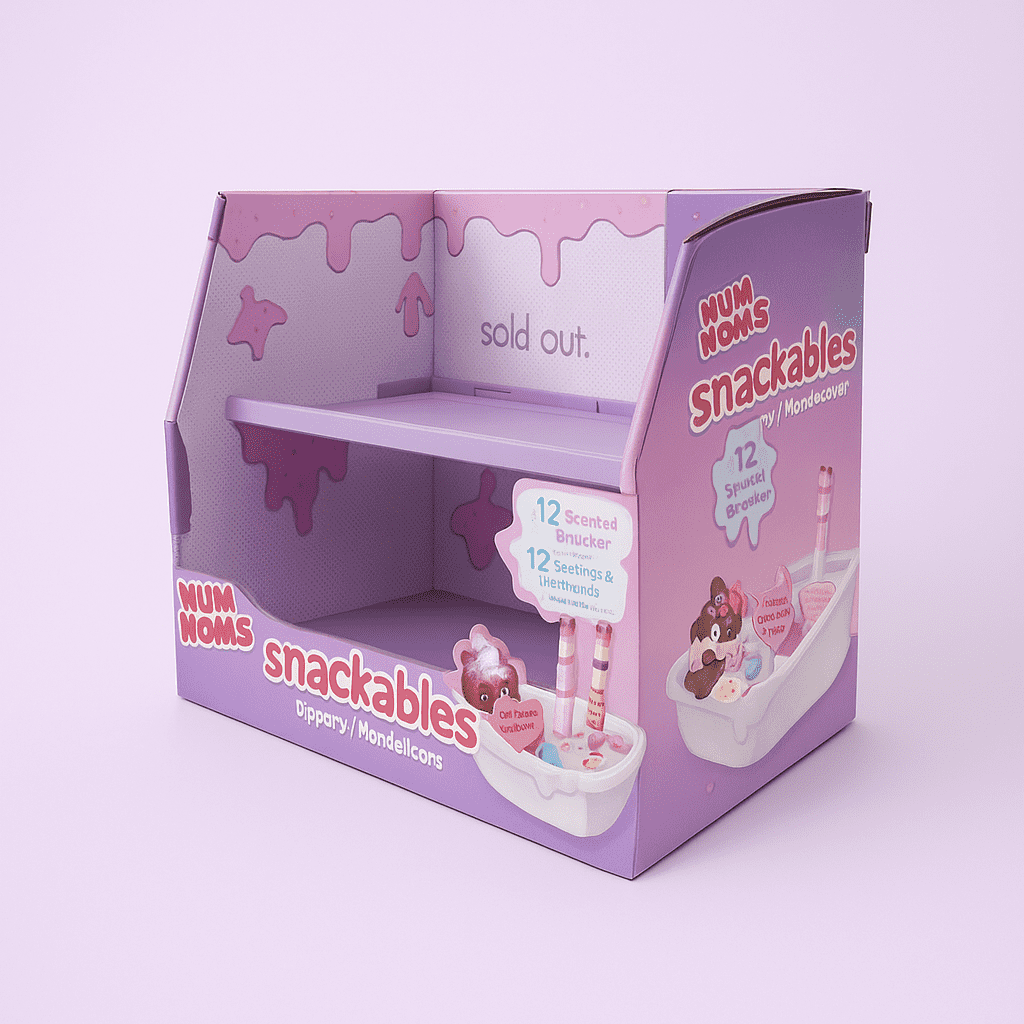

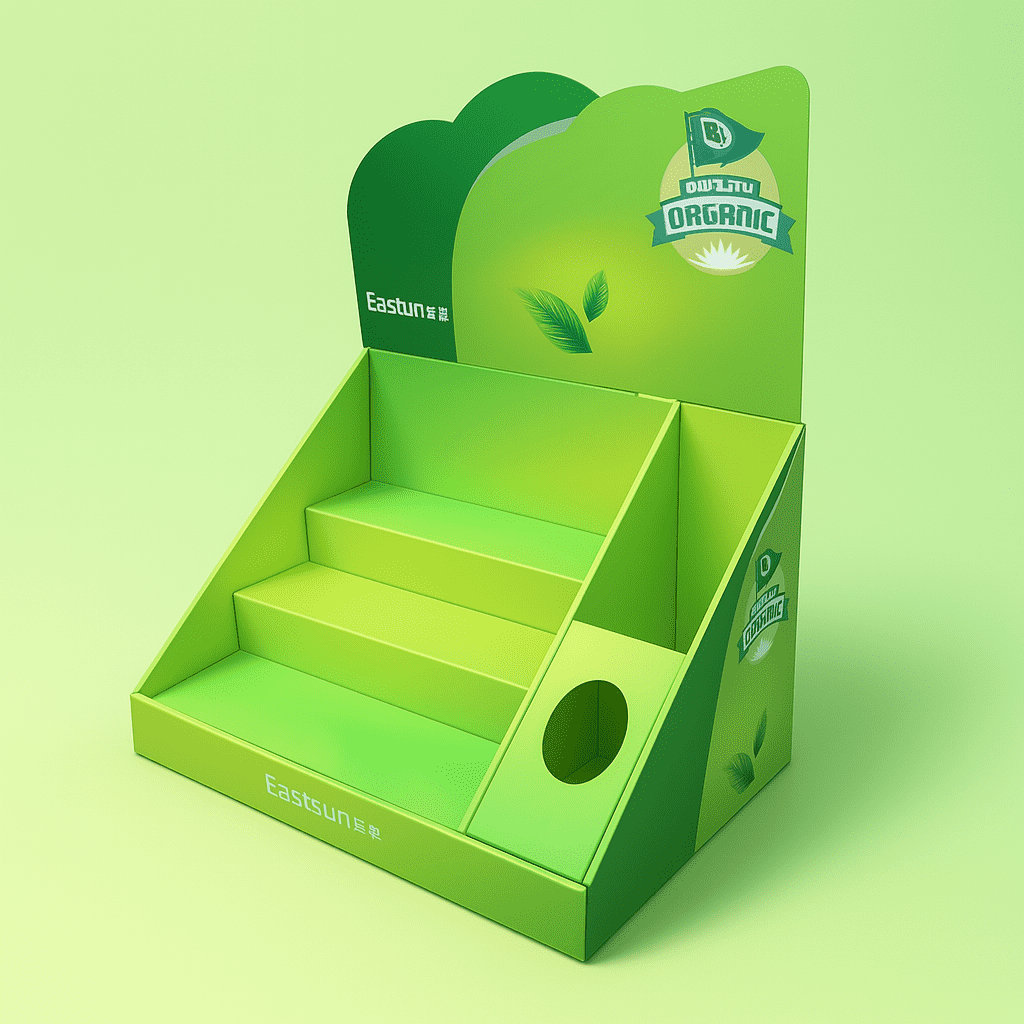

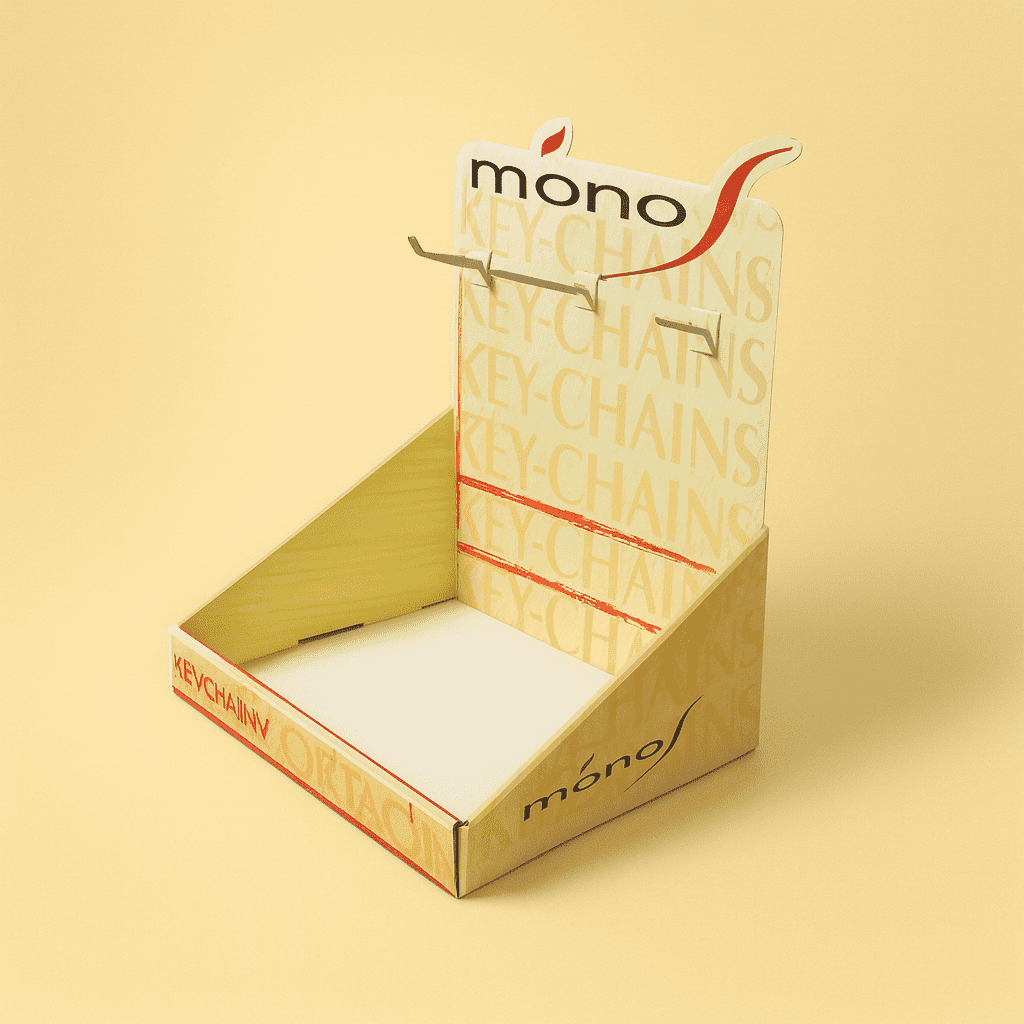

PDQ display

- Collapsible structure, saving transportation cost.

- Use corrugated cardboard which is stronger than boxes and can withstand more pressure.

- The diverse appearance and multiple colors printing options of display stands can effectively attract consumers’ attention and help shape the brand image.

- FSC certified material, environmentally friendly and recyclable.

Demand consultation

The customer sends a contact email to get the consultation.

Solution Design

The business manager conducts content docking with the customer.

Professional implementation

We make a samptle according to the customer’s requirements and confirm the details.

Successfully placed order

After the customer’s confirmation,the customer pays the deposit and places the order.

Paper board

SBS C1S

SBS C2S

CCNB

Brown Kraft

Metallic

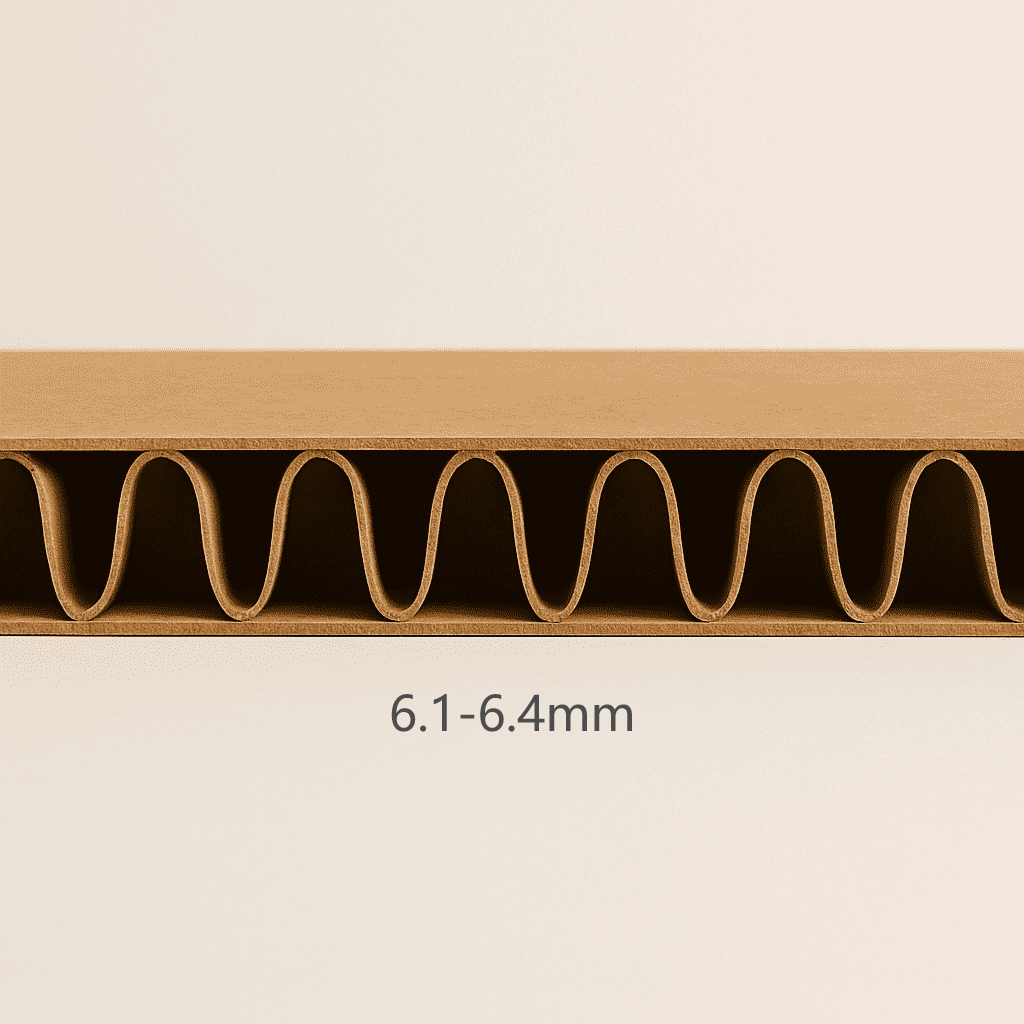

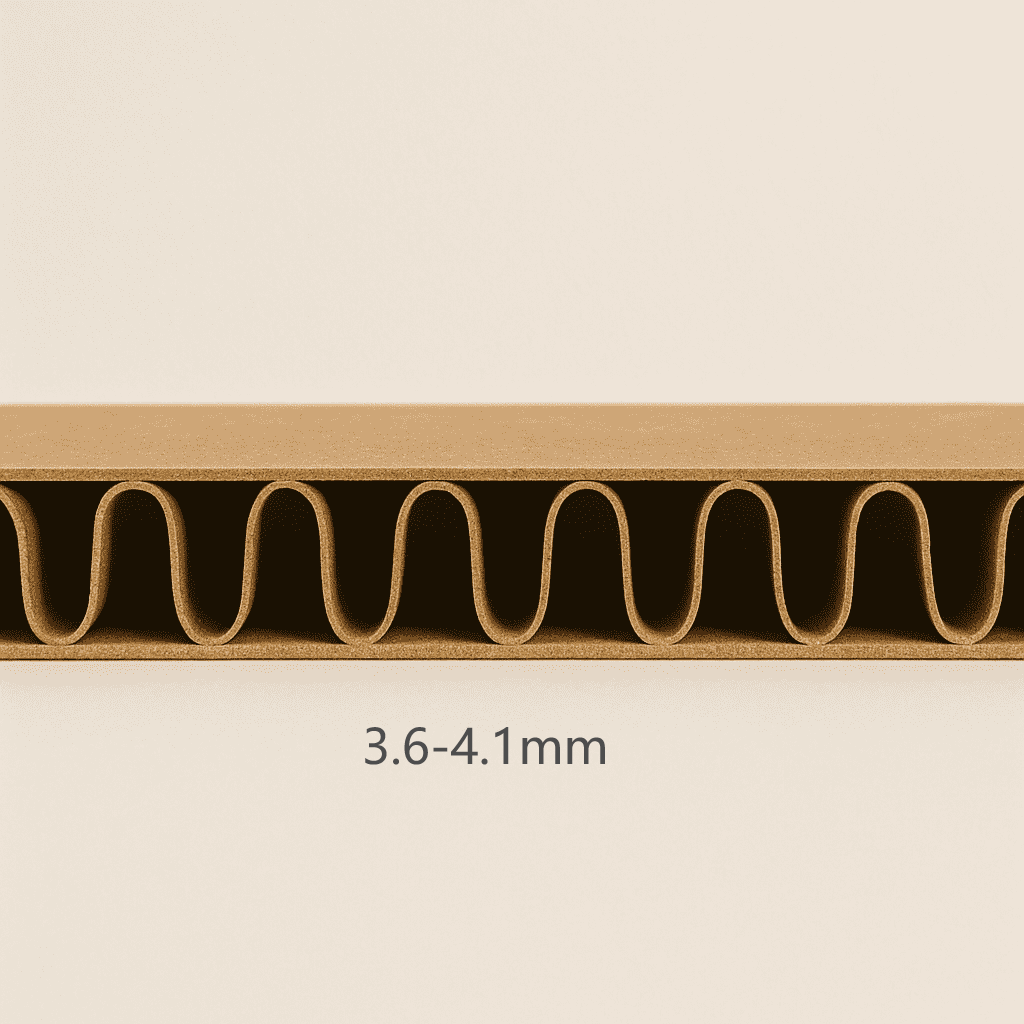

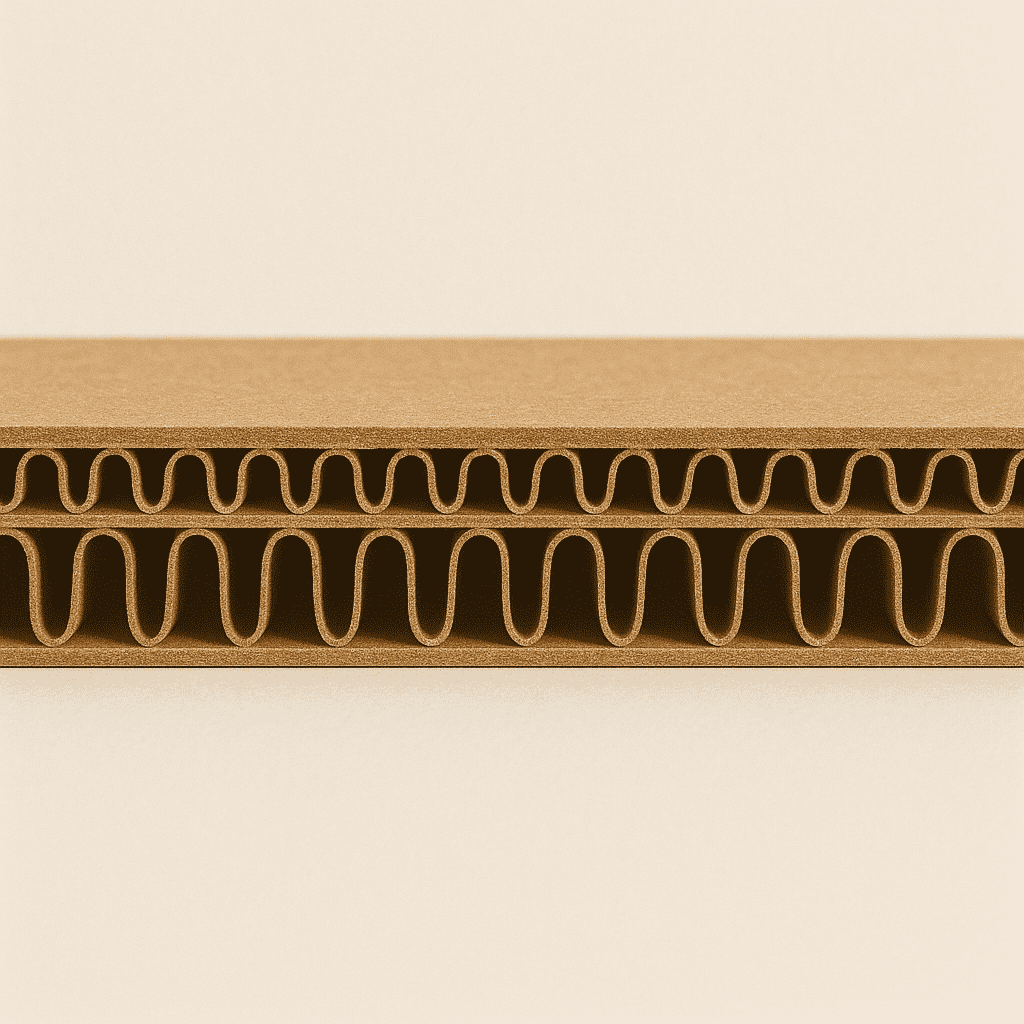

Corrugated

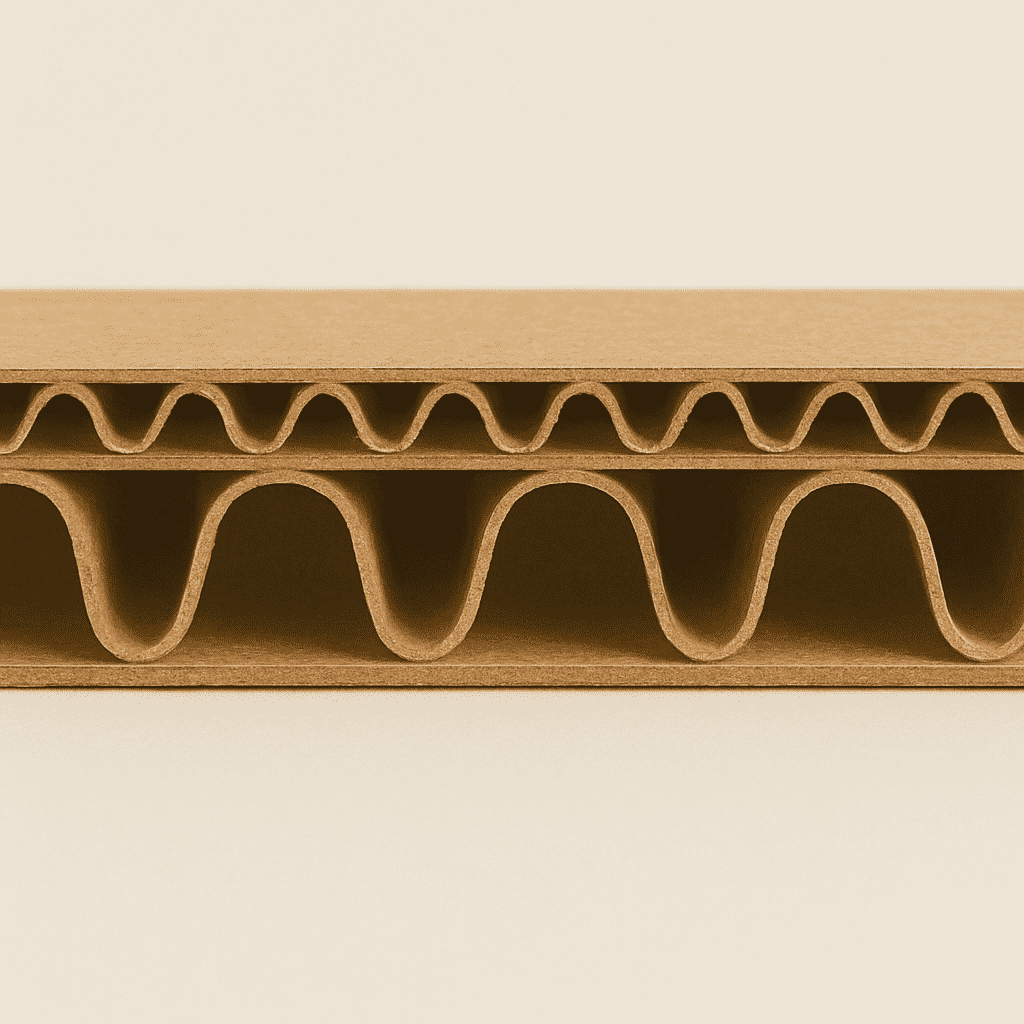

single wall

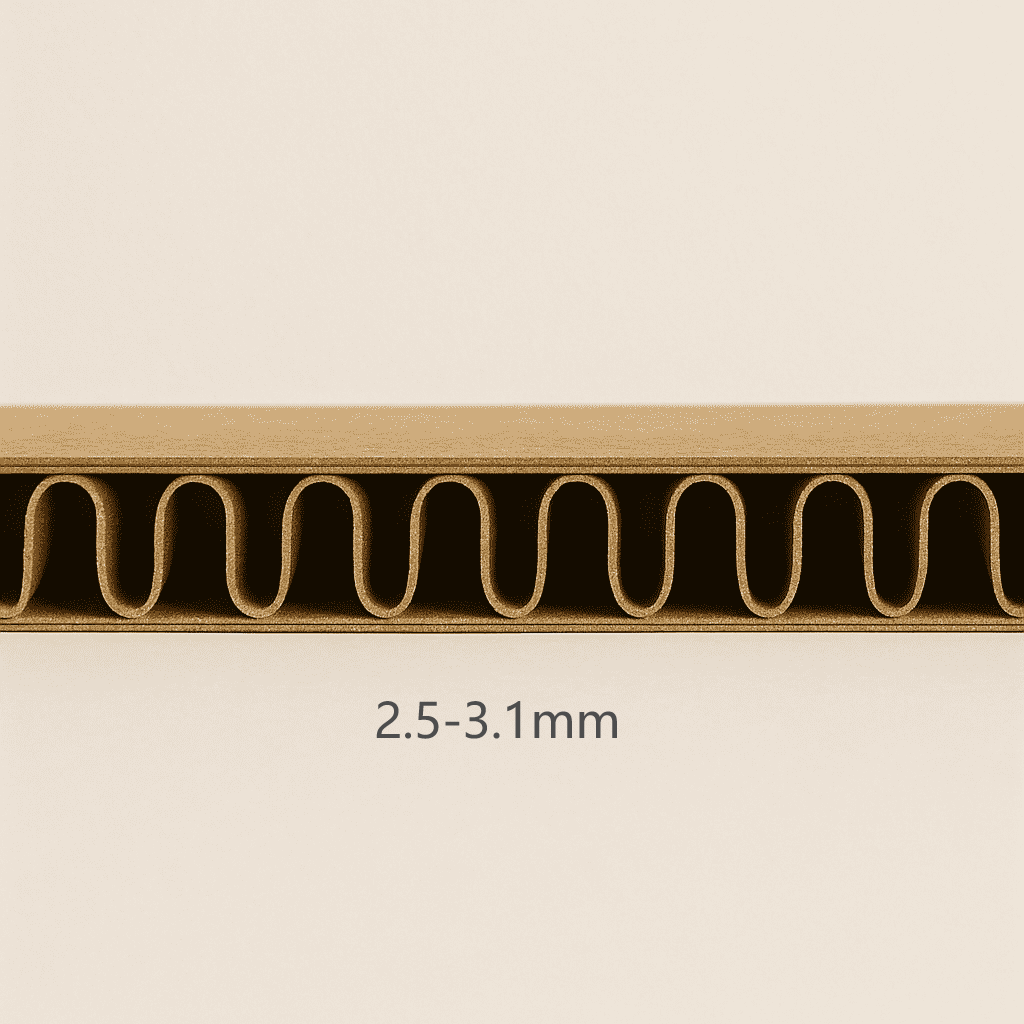

A Flute

C Flute

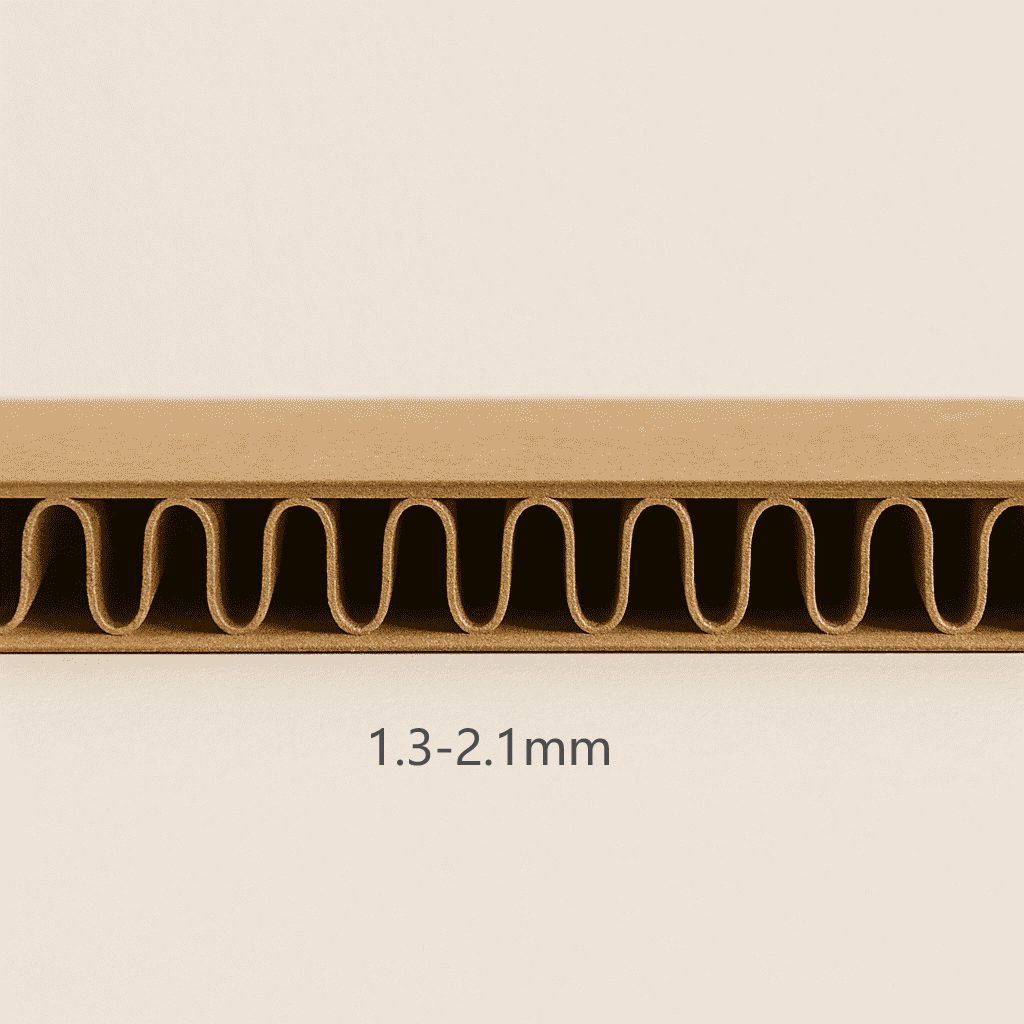

B Flute

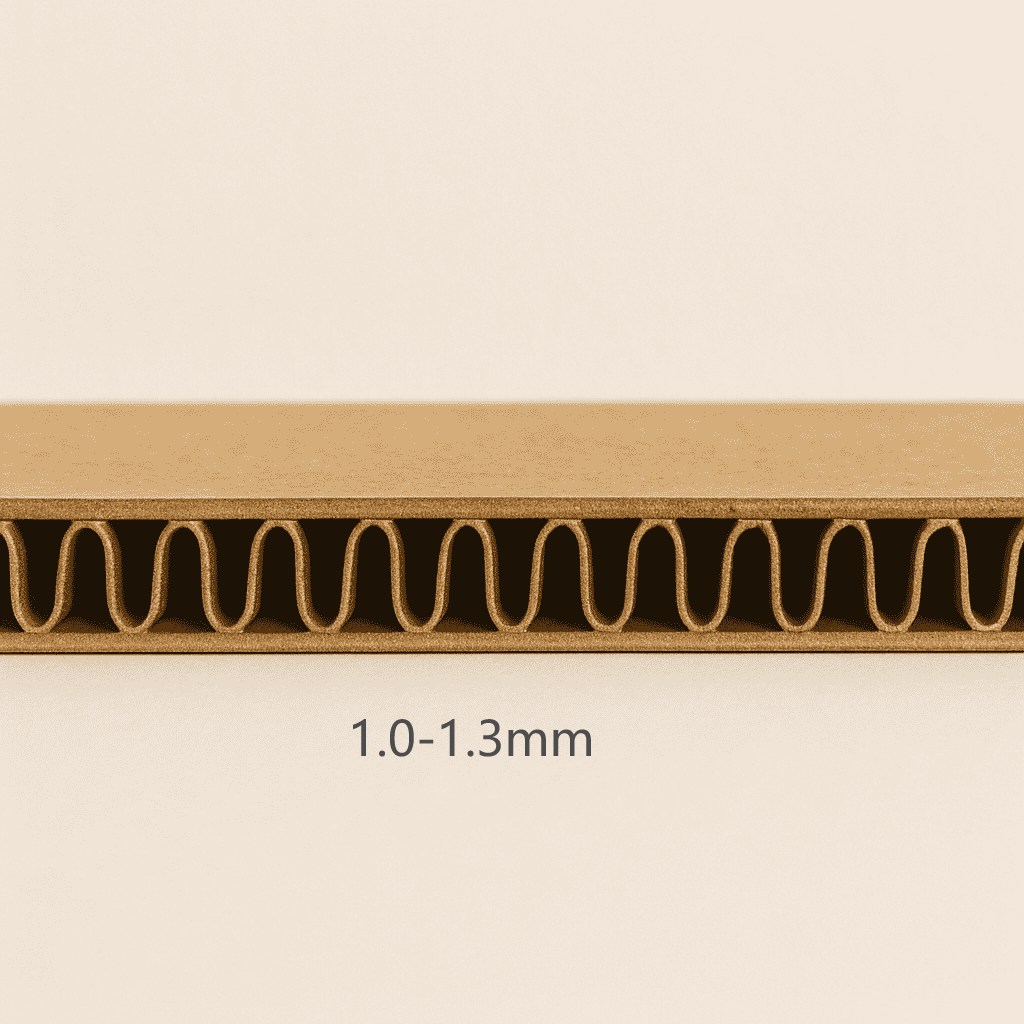

E Flute

F Flute

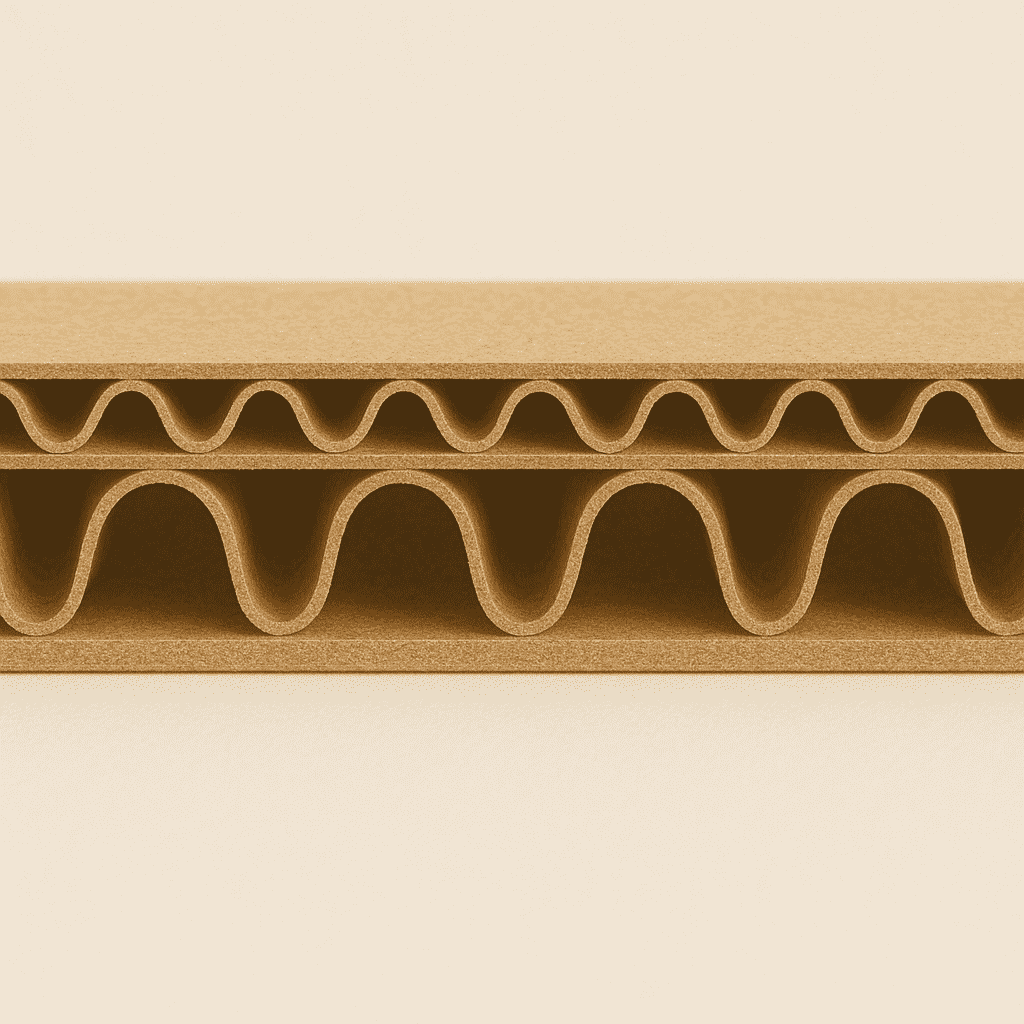

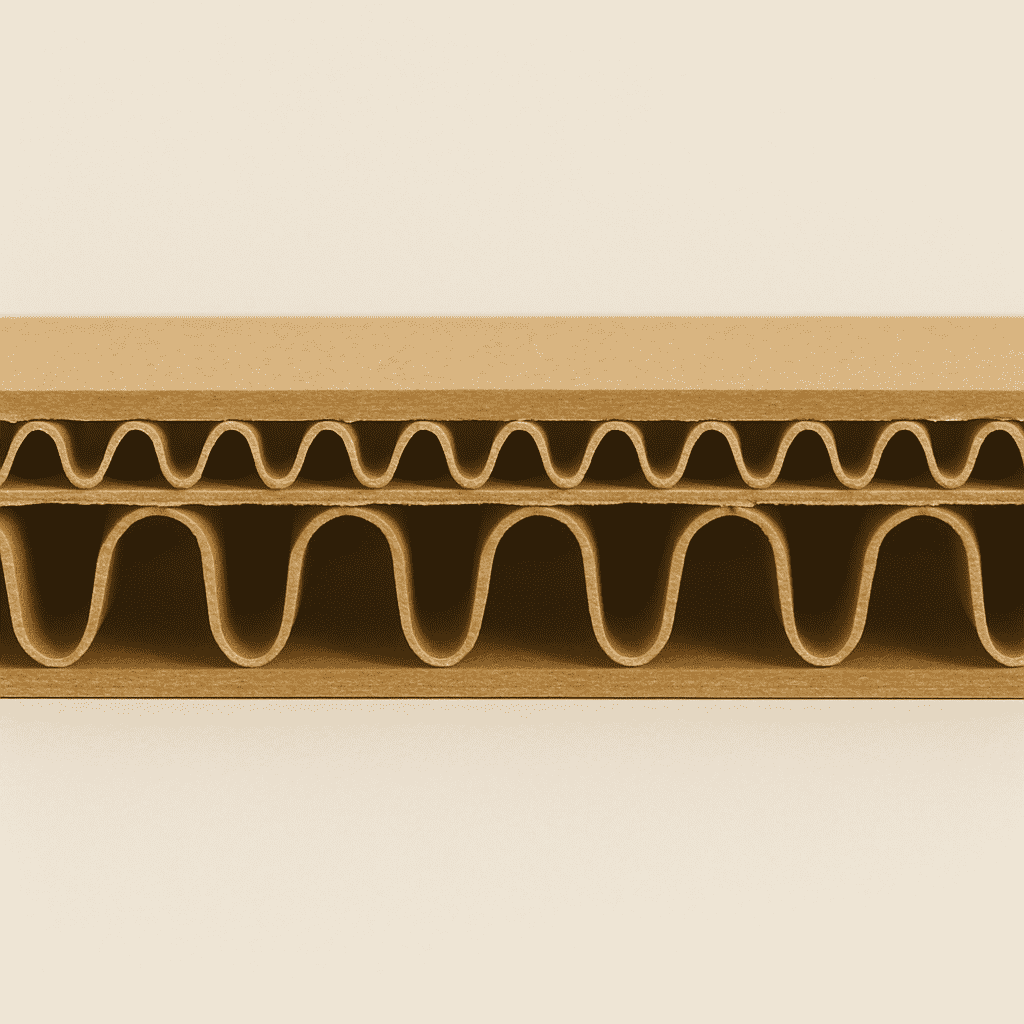

double wall

B/C Flute

E/C Flute

E/B Flute

F/E Flute

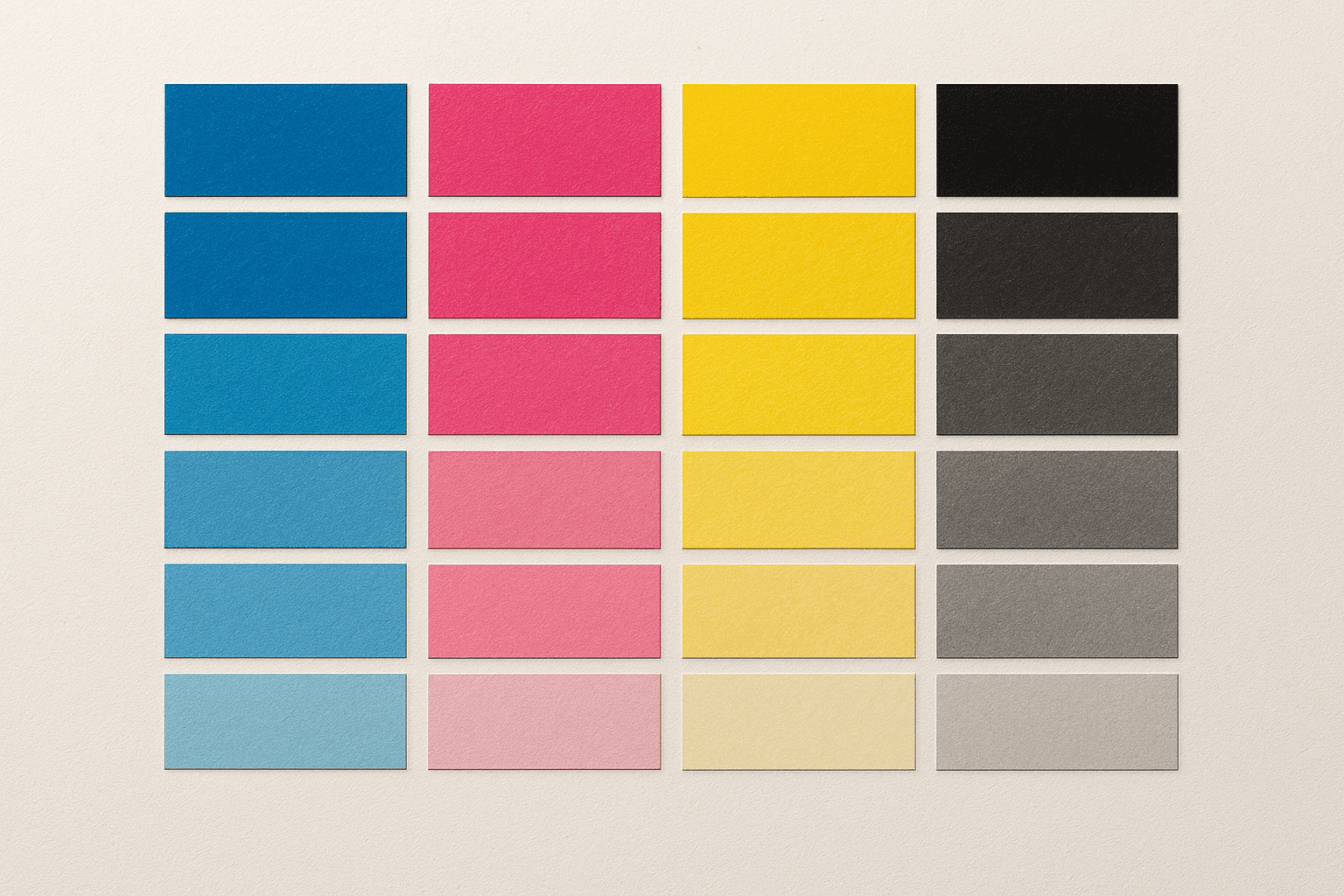

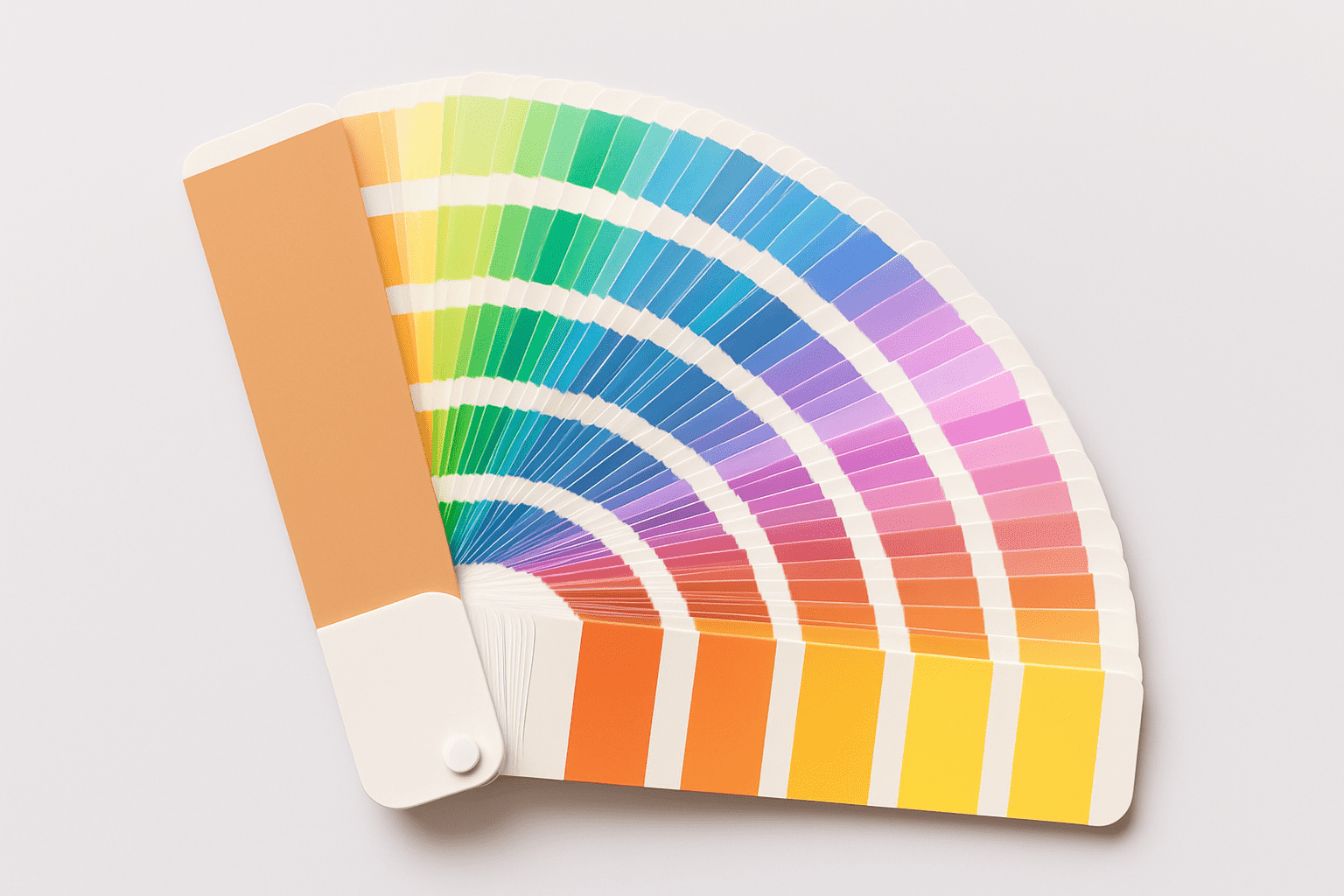

CMYK

Pantone

Lamination (Gloss/Matte)

– Applying a thin plastic film over the printed sheet to enhance scratch resistance, moisture protection and overall durability. Gloss lamination yields a shiny surface, while matte lamination gives a low-sheen, soft-touch effect.

UV Coating (Spot/Overall)

– Spreading a liquid UV-curable varnish onto either selected areas (spot UV) or the entire sheet, then instantly curing it under UV light. Creates high gloss and tactile contrast.

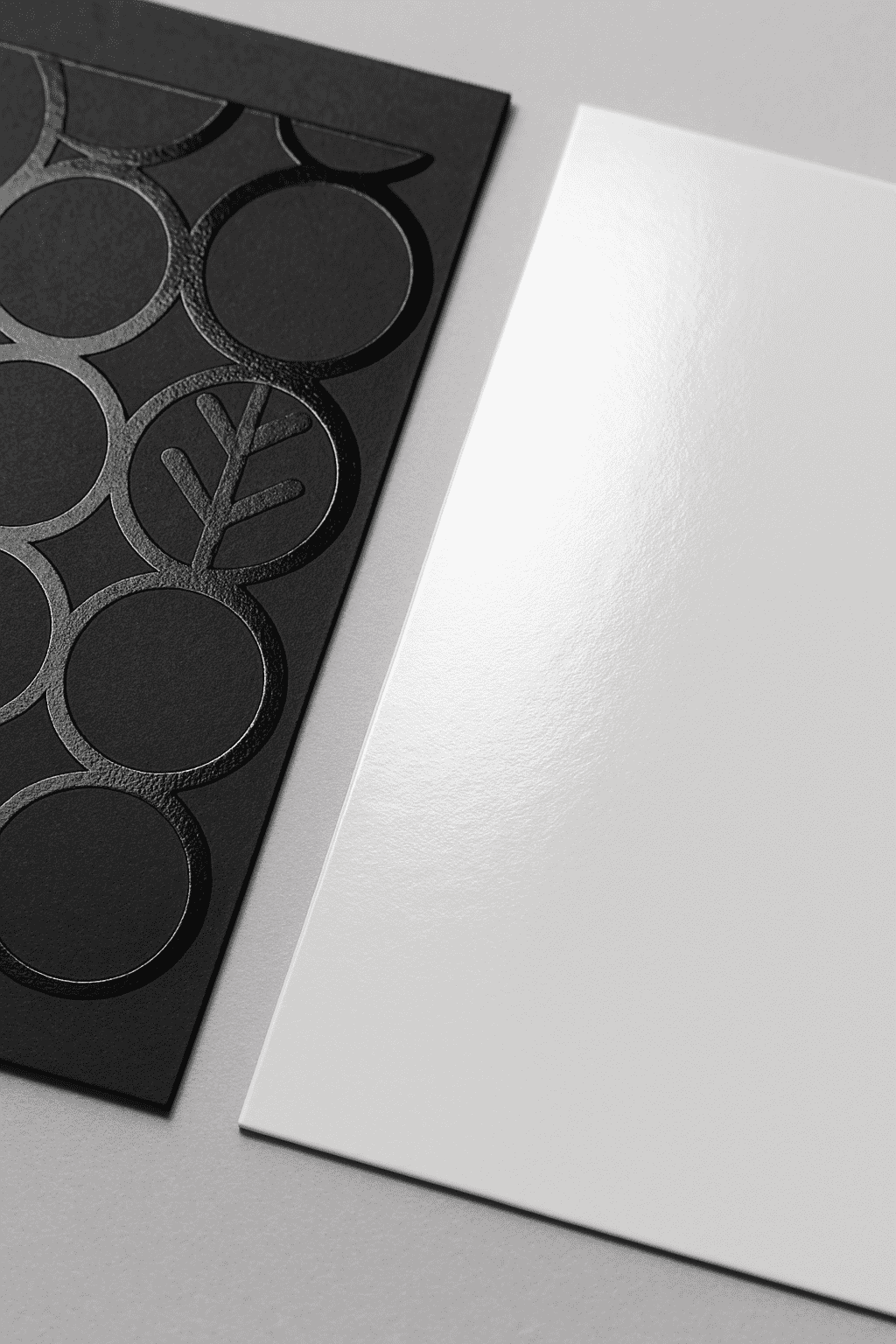

Hot Foil Stamping

– Transferring metallic or pigmented foil onto specific areas of the print using heat and pressure. Delivers a premium metallic sheen (gold, silver, colored foils) for logos or decorative accents.

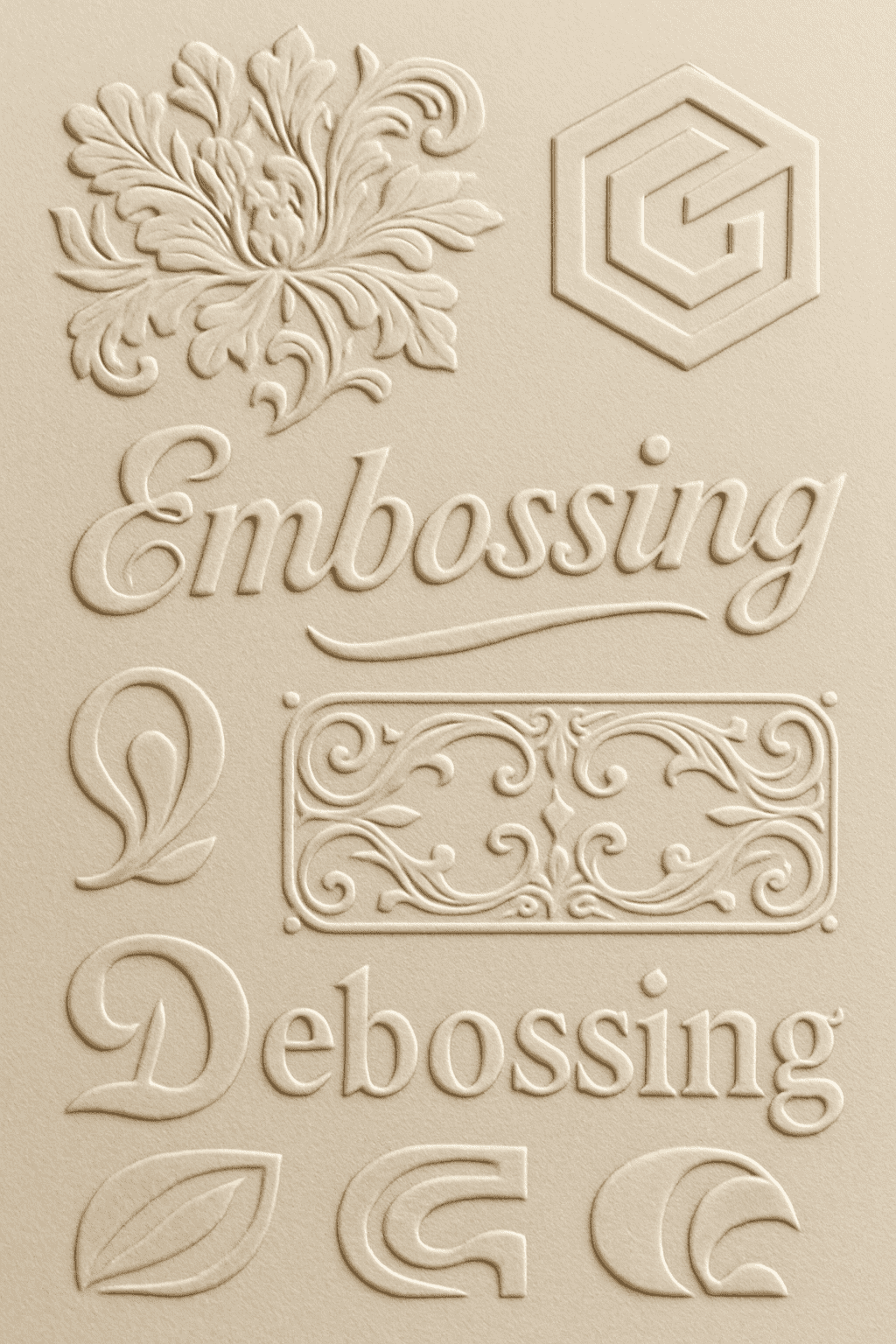

Embossing / Debossing

– Pressing the paper between male and female dies to create a raised (emboss) or recessed (deboss) 3D relief. Adds tactile interest and a sense of depth.

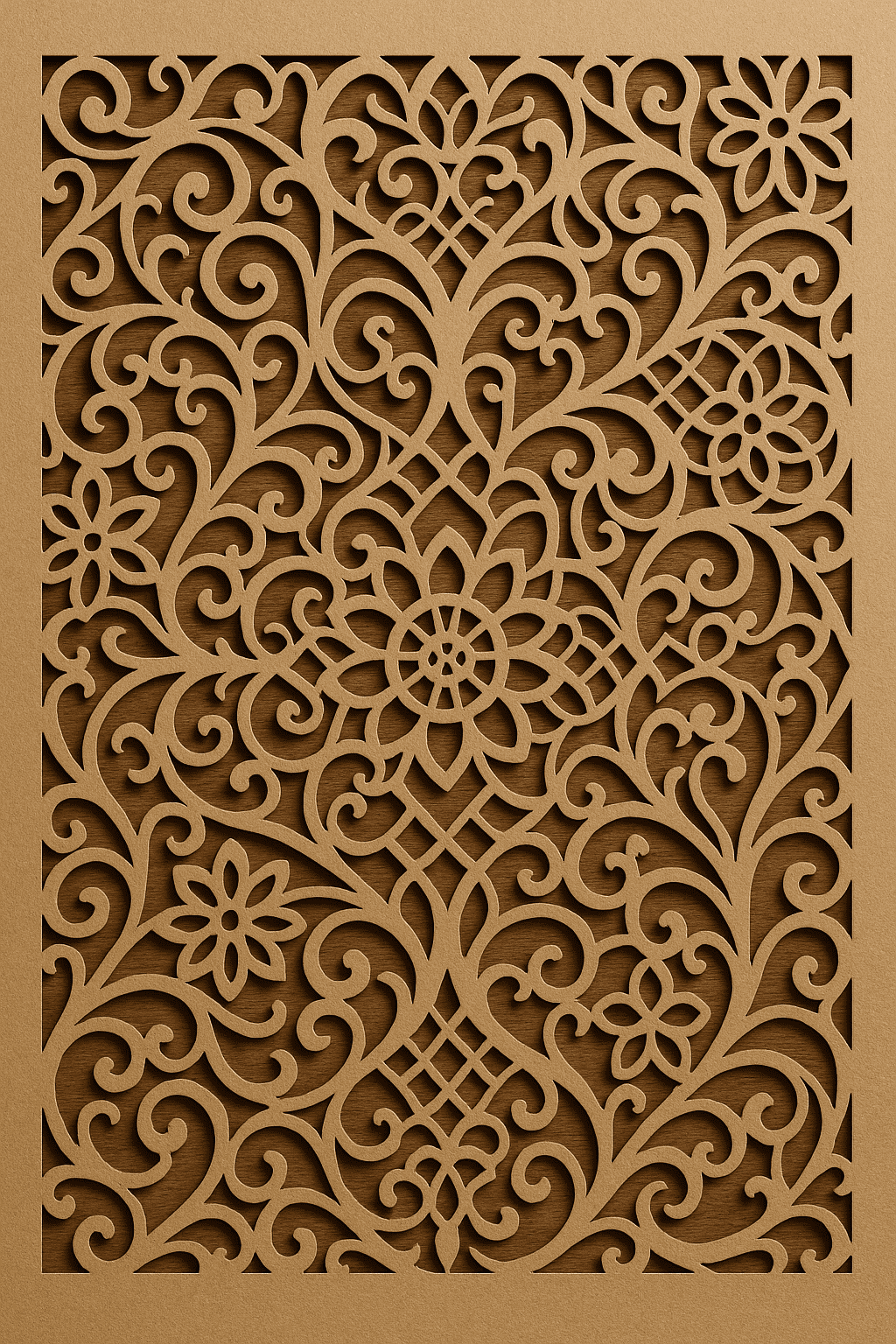

Die-Cutting

– Using a custom-made metal die to cut the printed sheet into precise shapes or create windows/slots. Essential for producing custom box shapes, hang-tabs, or intricate cut-outs.

Creasing (Folding Crease)

– Impressing a crease line on the sheet to facilitate clean, accurate folds without cracking the coating or ink. Critical for boxes, folders, and other folded structures.

Spot UV + Emboss Combination

– First applying spot UV coating, then embossing the same area to create a shiny, raised element. Enhances both visual shine and tactile relief simultaneously.

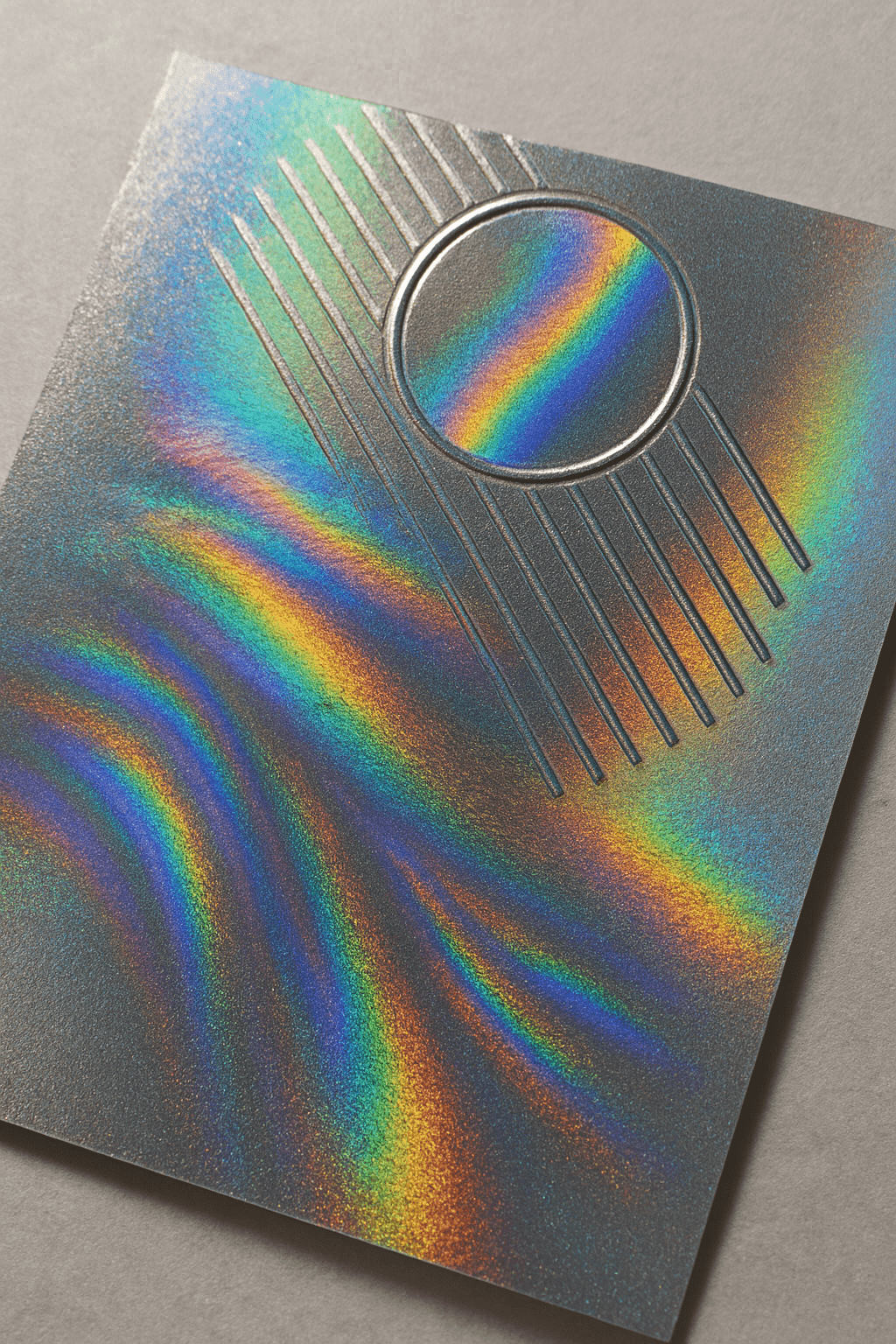

Holographic Foil Stamping

— Laser-etch microscopic holographic patterns onto foil, then heat- or UV-cure to lock in vibrant, angle-shifting colors and subtle texture for a premium anti-counterfeiting finish.

Our Advantage

Manual department

We have 100 all-round manual workers who can solve some difficult handmade gift boxes. We prevent homogeneity of customer brand packaging and have our own dazzling packaging.

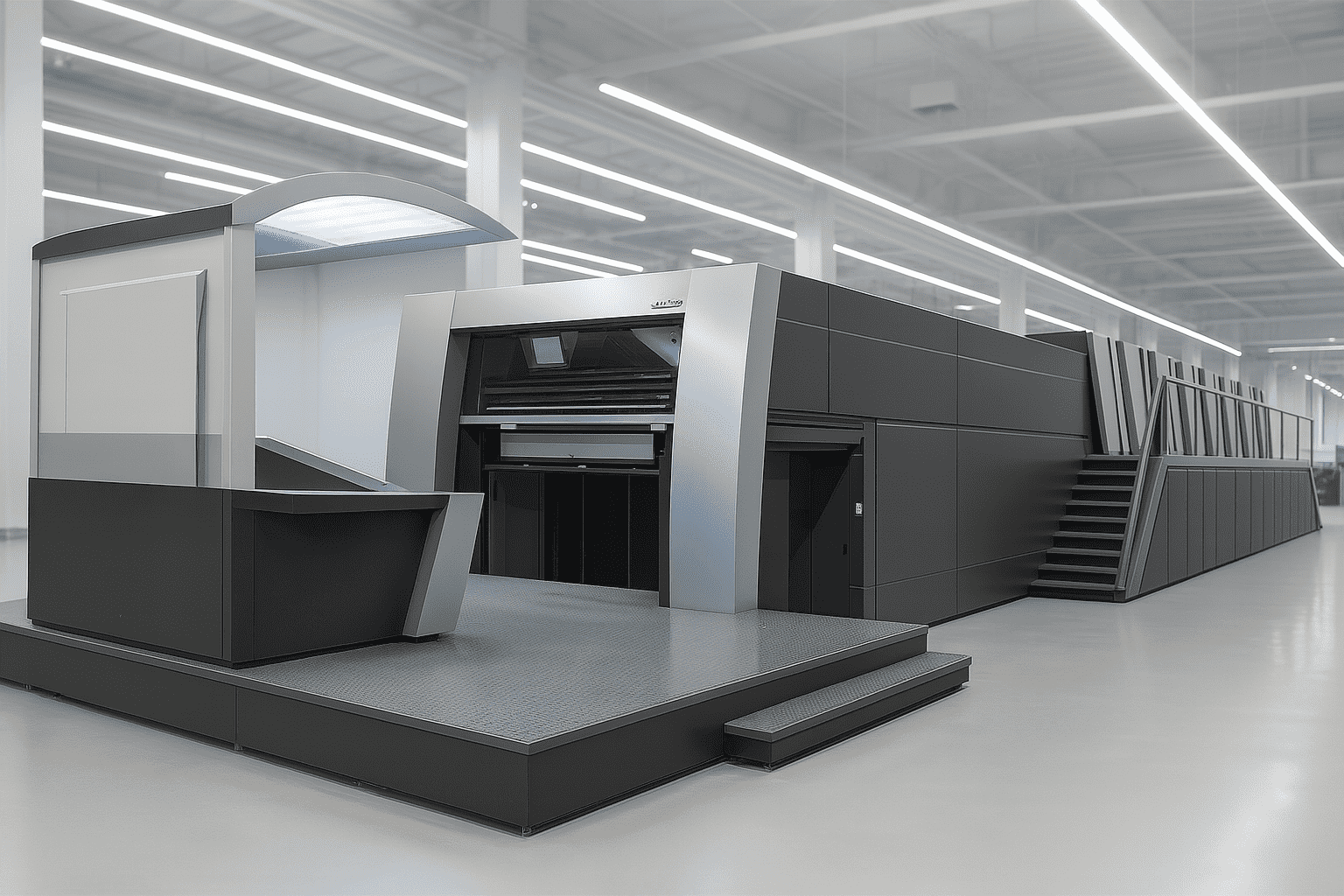

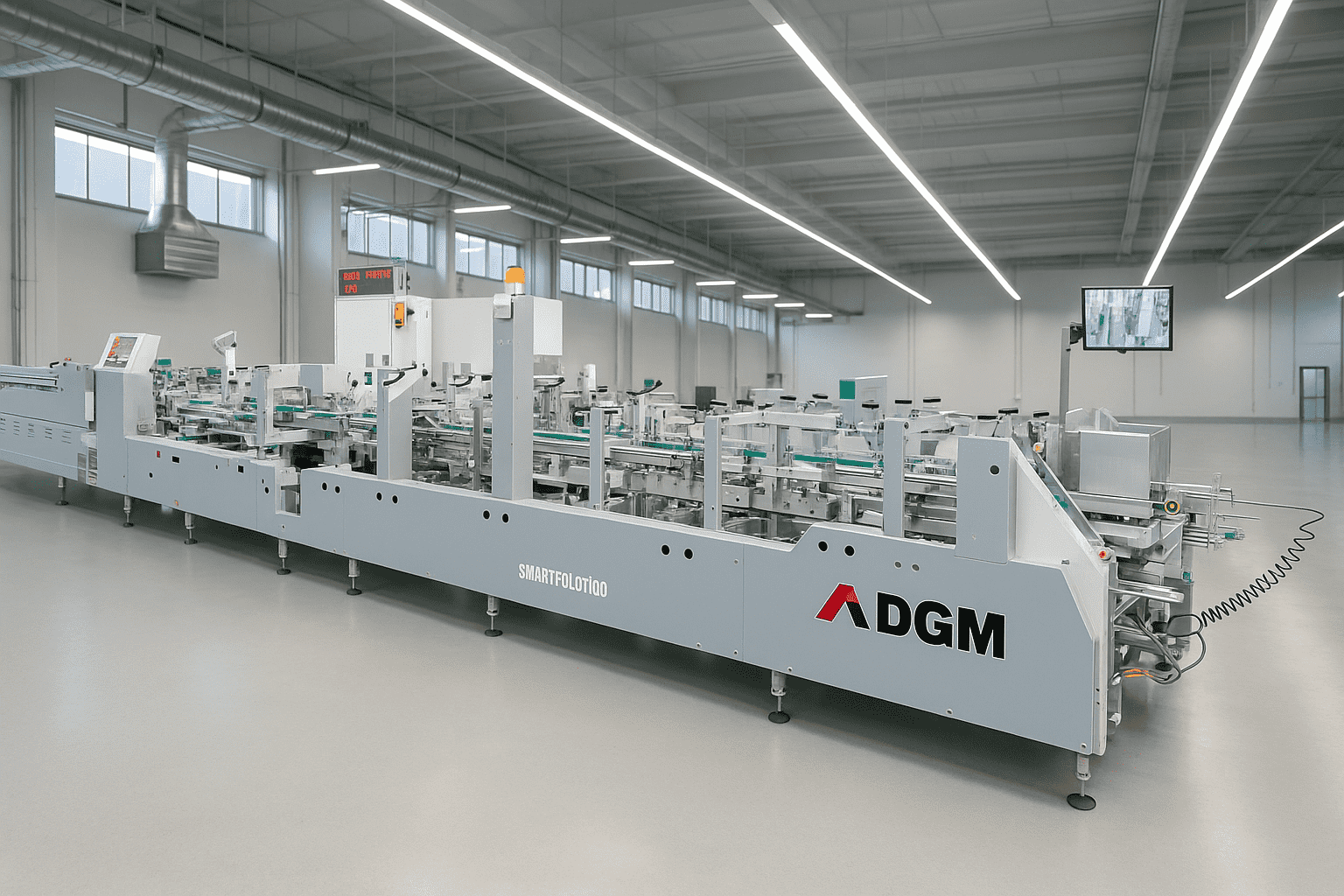

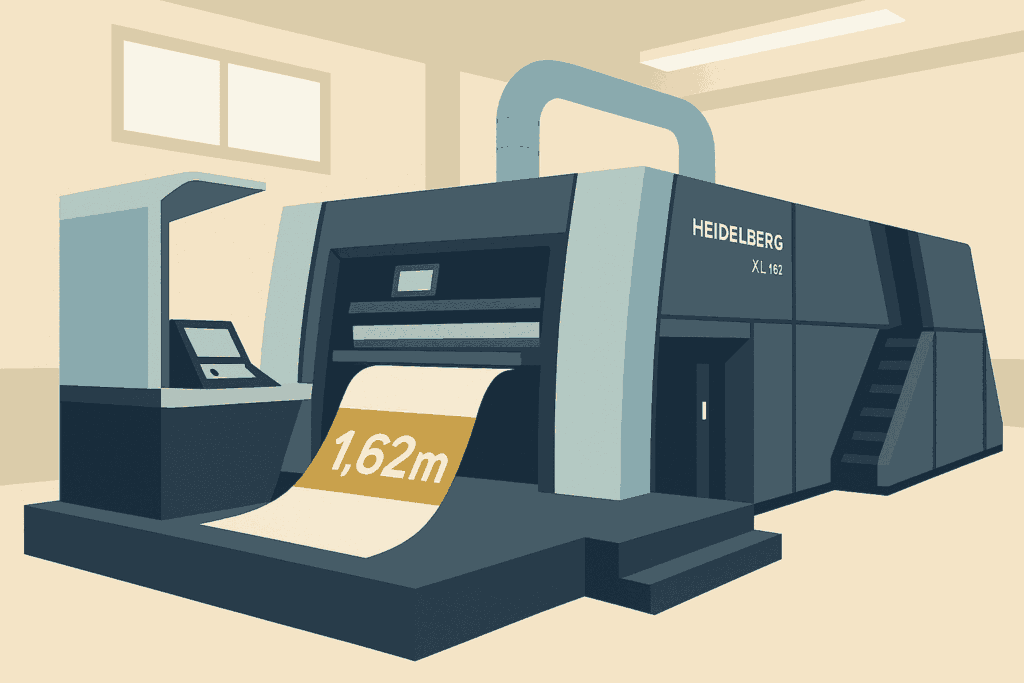

Printing machine

We have a German Heidelberg printing machine that can print within 1.62m width, which solves the pain point of packaging with large size and improves the overall printing efficiency.

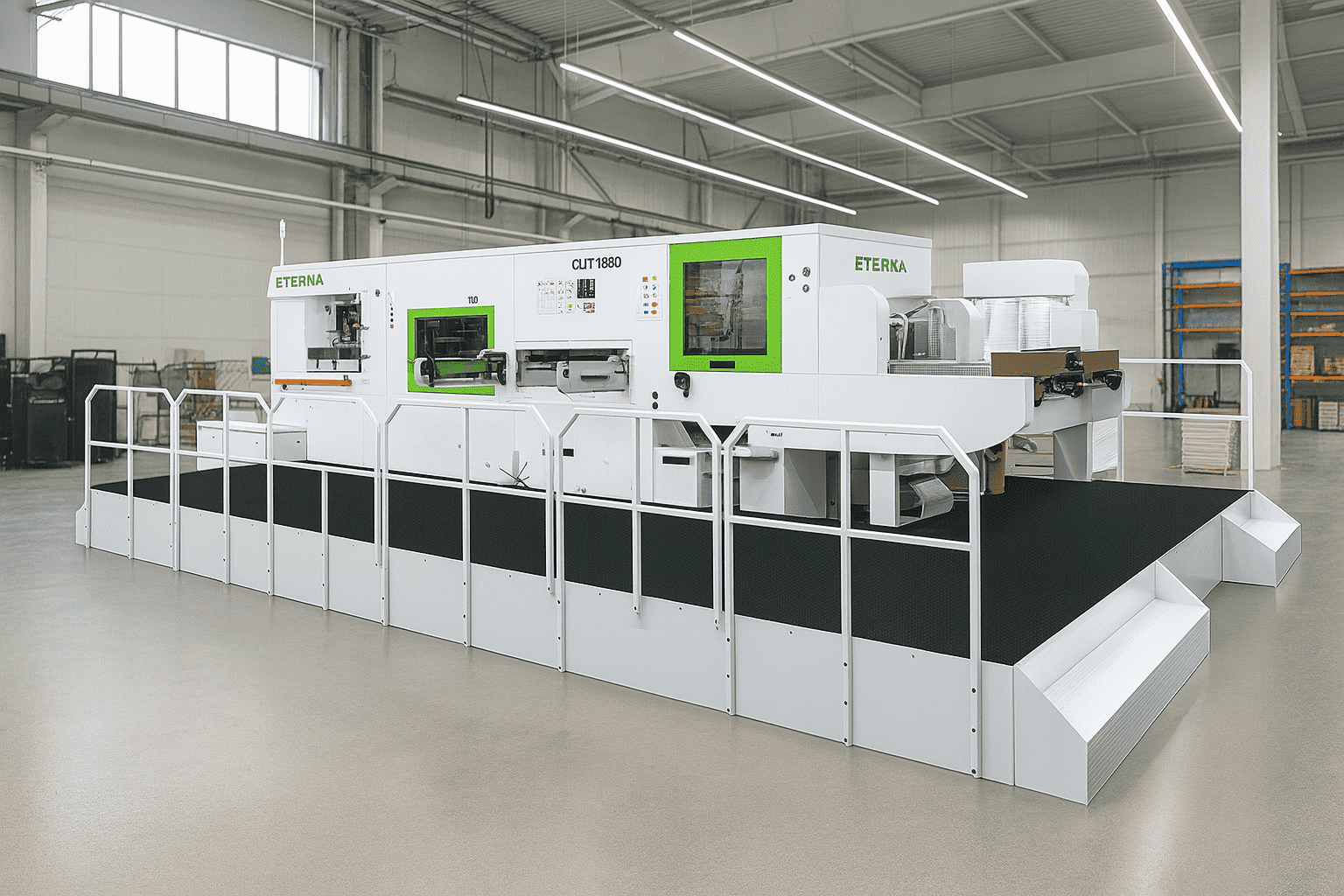

Automatic diecut machine

We have 15 fully automatic diecut machines of different sizes to solve the delivery efficiency.

Product Photos

F&Q

1. What is the minimum order quantity?

Our minimum order quantity is 1000 pcs.

2.How long will it take to deliver?

Our delivery lead time is 15 to 20 days.

3.What should I do if I can’t find the style I want?

Don’t worry—we offer personalized customization services.

4.Which payment options are available?

We accept payment by T/T, Western Union, and credit card.

5.What happens if the product I bought doesn’t match the agreed standards?

Our agreement includes rigorous liability and compensation provisions.

6.What should I do if I have special requirements?

Our staff have at least three years of packaging experience and can meet any of your needs.

7.What additional services do you offer?

We offer complimentary 3D model design services.